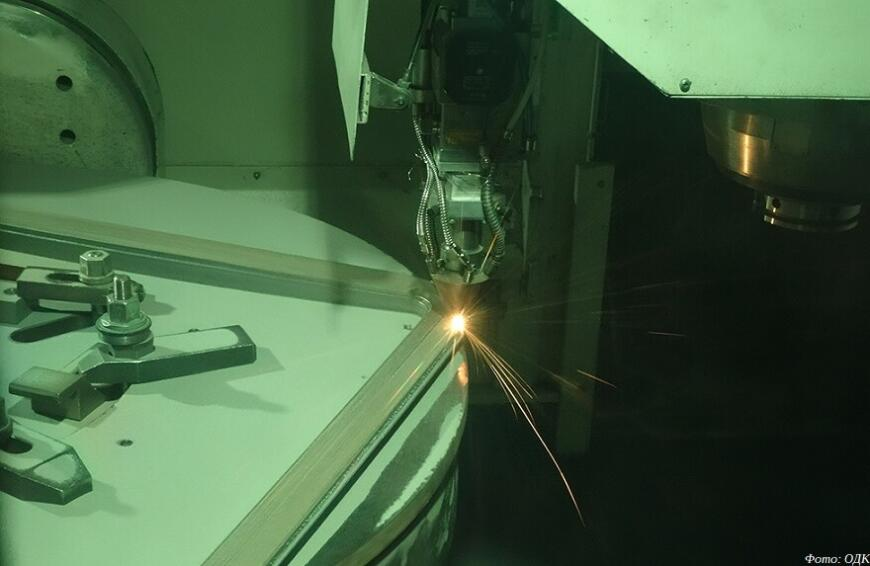

Research Institute of Technology and Organization of Engine Production (NIID, a part of United Engine Corporation, UEC, of Rostec) is continuing the research focused on using additive manufacturing technologies for aircraft engine production with the help of metal 3D printing. The hybrid manufacturing system was launched in 2020 and so far it produced 11 full-size billet engine parts.

After a year of operation, the experts of the NIID managed to produce 11 full-sized billets that were sent to the ‘Salyut’ factory complex for further tooling and testing.

Sergey Pavlinich, the director of NIID, said: “Using a hybrid manufacturing system made it possible to avoid integration of large billet casting manufacturing at the Salyut factory complex, as well as integration of expensive equipment production. Development of each test billet at the NIID took up to 1.5 months, while traditional manufacturing of every part would take around a year. Moreover, the experts of the NIID developed unique billet manufacturing methods that exceed the capabilities of serial equipment. Other innovations included the new ways to manufacture complex large-sized and thin-walled billets.”

Aside from producing new billets, the workers of the NIID are doing the research on using additive technologies to repair aircraft engine parts. The NIID is planning to widen the range of works by integrating a new additive system that will allow the Institute to produce billets from titanium and intermetallic alloys.