What is 3D printing?

3D printing is a new way of manufacturing solid objects based on the principle of discrete-stacking.

With the evolution of the trend, 3D printing has become a way to promote smart manufacturing, flexible manufacturing and green manufacturing. It can realize the integrated formation of complex structures that are difficult to process or even cannot be processed by traditional manufacturing technologies, greatly enhancing the process realization capability. Subversive advancement in equipment design and manufacturing.

From the past used to manufacture models, and now gradually realize the direct manufacturing of products, 3D printing manufacturing technology is developing towards the integration of “design-material-manufacturing”. According to research, the size of the world 3D printing market in 2017 was 3.86 billion US dollars. In 2018, the scale of China's 3D printing market was as high as 7.75 billion US dollars, which has more than doubled in two years. From behind the scenes to the forefront of the industry, the development of the 3D printing industry has moved from the concept introduction period to the rapid development period, all thanks to: "application." Members of the World 3D Printing Association have said:

“When 3D printing technology goes out of the lab,

Its development motivation lies in its application”

Today, I will focus on the diversified applications of 3D printing.

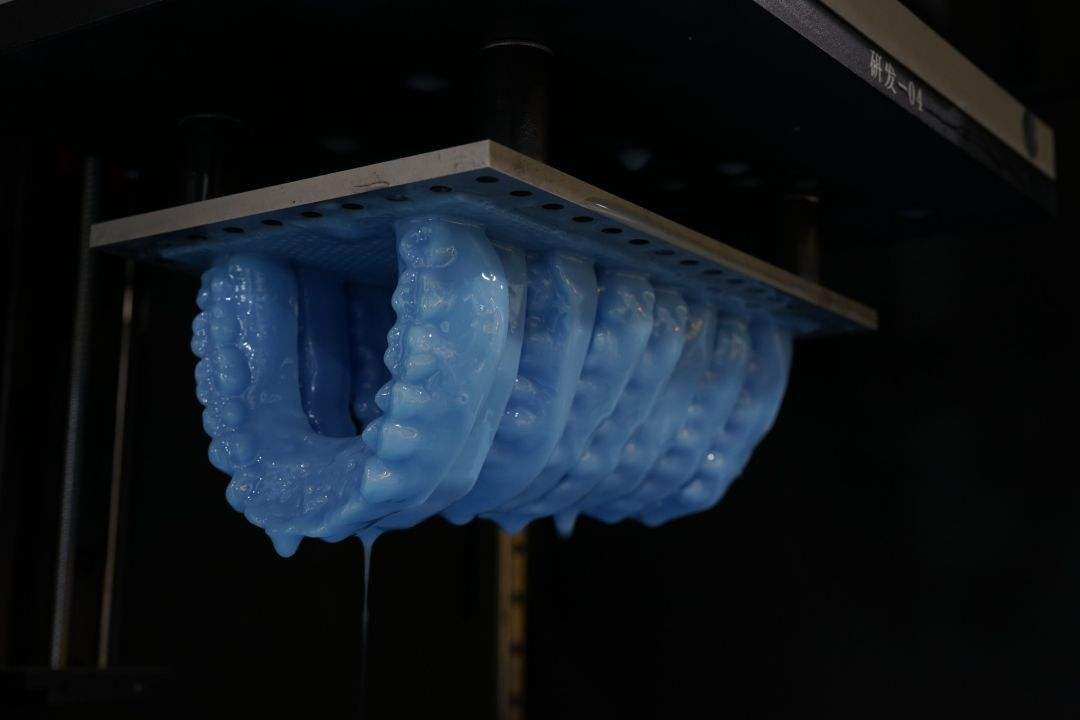

3D printing applications in the medical industry

The medical industry has always been the mainstream application area of 3D printing technology. According to market research reports, the global dental 3D printing market reached US$903 million in 2016, and will reach US$3.441 billion in 2025, with a compound annual growth rate of 16.5%.

3D printing technology has the characteristics of high flexibility, unlimited quantity and cost saving, which can meet the needs of individualized and precise medical treatment in medical field. Especially in the field of oral medicine, 3D printing has a subversive effect on oral materials, processing methods, physician skills, surgical forms and other aspects. 3D printing technology enables digital stomatology to achieve a leap from virtual simulation to real-world simulation, and is an important means to achieve precise medical care. At present, the application of 3D printing in the field of oral medicine can be roughly divided into three levels:

- Applicable in general and commercial, with medical models, surgical guides and dentures as the representative, mature and less risky.

- Applied in clinical research, represented by three types of medical device implants, the need for clinical, process and other aspects of data accumulation and improvement.

- Application in laboratory research, represented by tissue organs, represents the future development direction.

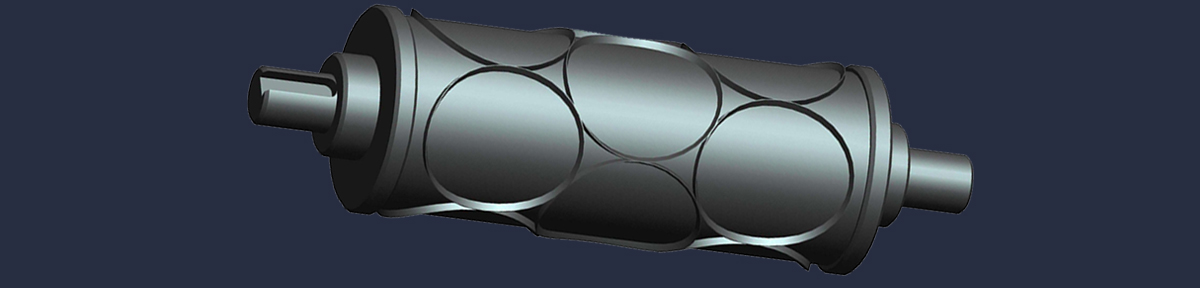

3D printing applications in the consumer electronics industry

Since the development of 3D printing, it has been able to bring enough transformation and development momentum to the traditional manufacturing industry. In particular, there have been some excellent applications in consumer electronics, and its potential is even more exciting!

The electronic consumer industry has the characteristics of short product life cycle and fast replacement, which requires continuous development and investment characteristics. 3D printing can meet the needs of small and medium-volume, fast-production and high-complexity products in the electronic consumer industry. With 3D printing technology, you can improve the design level, shorten the product development cycle, and reduce the design cost. With the development of 3D printing technology and materials, and the increasing personalization requirements, 3D printing will be used more for direct manufacturing. The consumer electronics industry is of great significance. Looking into the future, 3D printing technology can be said to be a new direction for the transformation and upgrading of the traditional electronic consumer industry, which will greatly simplify the cumbersome division of labor in the industrial era, and the continuous release of personalized demand, human society will eventually usher in the era of mass customization.

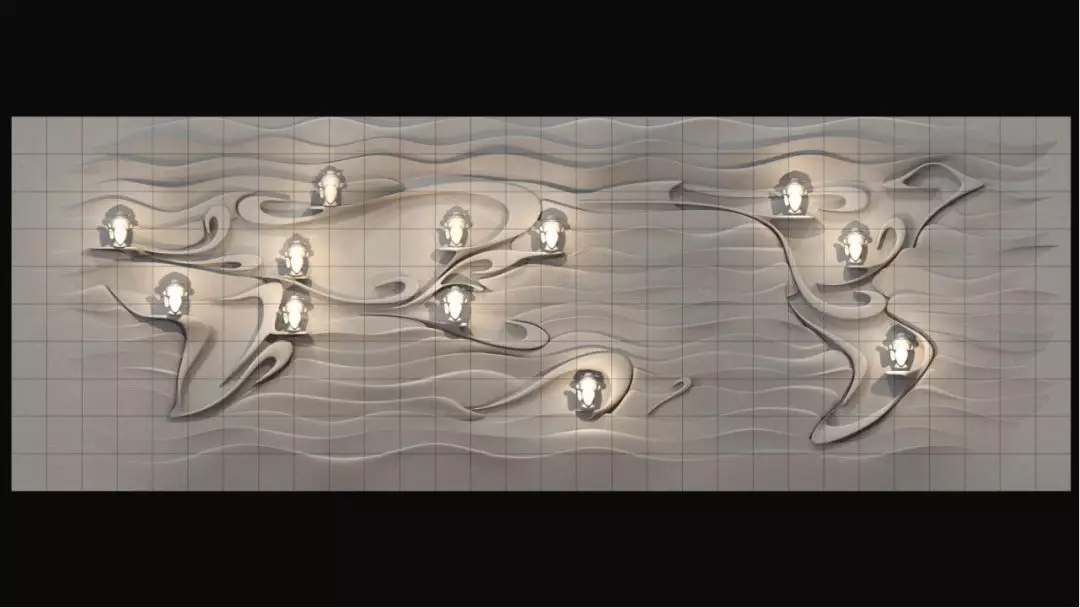

Application in the field of cultural creativity

3D printing is used in a wide range of cultural and creative applications, including personalized customization and manufacturing, as well as the production and manufacture of modern art such as jewellery, as well as the reproduction of ancient art, such as high-end art such as artifacts. Derivatives. The significance of applying 3D printing to the cultural and creative industries is very significant.

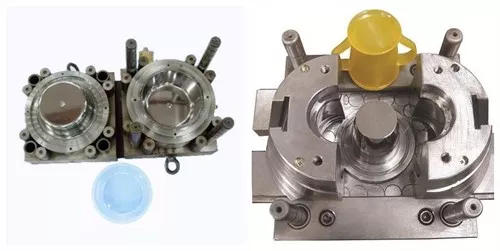

Application in the mold industry

CNC machining is the most common technique used in the manufacture of molds. Although it provides highly reliable results, it is also very expensive and time consuming. So many mold manufacturers are also looking for more effective alternatives, 3D printing technology is a good alternative.

The 3D printing model covers several advantages, including:

- The mold production cycle is shortened;

- reduced manufacturing costs;

- Improvements in mold design add more functionality to the end product;

- The optimization tool is more ergonomic and improves the minimum performance;

- Customized molds help to customize the final product.

It has been widely used in automotive, aerospace, and healthcare and medical care, and many companies have integrated 3D printing into their supply chain, including mold manufacturing.

3D printing technology in the automotive field

Among the many applications of 3D printing technology, the automotive industry is one of the earliest applications of 3D printing technology. As early as the development of 3D printing technology, some European and American countries began to apply 3D printing technology to the automotive research and development process. Currently, the application of 3D printing technology in the automotive industry runs through the entire life cycle of the vehicle, including R&D, production and use.

In terms of application range, the current application of 3D printing technology in the automotive field mainly focuses on the experimental model and functional prototype manufacturing in the research and development process, and there are relatively few production and use links. In the future, 3D printing technology will continue to be widely used in prototype manufacturing in the automotive field.

The above, just some of the applications of 3D printing technology, which has been the focus of the times, is gradually becoming an important model for manufacturing production and an important technology to lead the era of intelligent manufacturing. With the gradual deepening of 3D printing applications, companies with a high degree of industry mission are urgently needed as pioneers.