Andreas Muller, 3D printing enthusiast, developed an open-source project that makes color printing with regular FDM 3D printers possible with the custom system of replaceable printheads and permanent color marker pens.

If you can’t afford the Palette splicers of buying multi-material 3D printers by Prusa Research, you can try this simple project that requires only having a simple budget 3D printer and a set of marker pens. There is no need to rebuild the 3D printer itself, just a small modification will make it possible to paint the models during the printing process with the help of several marker pens (up to six). This is how it works: a device produces a layer and then paints the plastic with a marker, parks it and repeats the process. Overall, it’s similar to the solution used by the XYZ 3D printers but the latter involves the heads of regular inkjet printers. This results in a more expensive solution compared to the one offered by the 3DPrintColorizer project, albeit with more colors options available.

The hardware side of things is quite simple: print the connectors and buy permanent marker pens. The project author uses the Ender-3 and places the marker pen cartridge right above the BLTouch sensor connector. If your 3D printer does not feature the BLTouch sensor, you can 3D print the connectors, install it and then make the pen cartridge. Another requirement is the parking platform and the connectors that make the pens stick to the platform during parking. There are solutions available for Amazon Basics, Sharpie and Shuttle Art pens.

Modifying G-code would require using a special add-on for Cura that imitates multi-material 3D printing. This means generating additional “extruders” that would actually be used for the marker pens. How many? The same as the number of pens. Then a user should set the values for parking and extruder offset. The retraction value is better to be upped in case the nozzle will produce too much material during the painting stage. Adding additional walls and setting the infill parameter at least at 40% would also be useful to compensate for the lowered adhesion of the painted layers.There is no need to paint whole layers, just a couple parameters would be usually enough. But this can be changed manually as well.

Another interesting function is the ability to color only every second layer. According to the developer, it would be enough for most cases and help avoiding mixing the colors after pen change. But coloring every layer can be done if needed, resulting in more saturated paint.

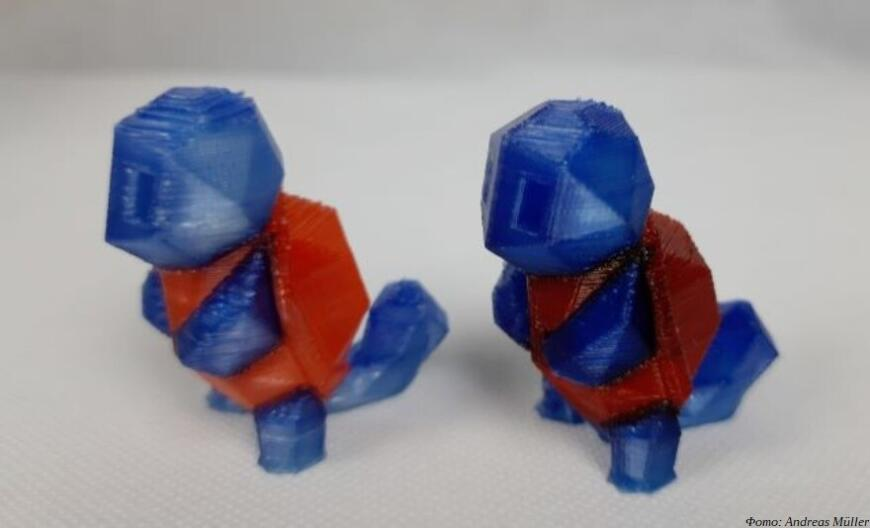

The result after painting every second layer (on the left) and every layer (on the right).

It’s not clear yet what materials are supported. The developer uses the PLA filament. One thing is certain is that it is better to use the neutral-colored filament for better color reproduction. White or transparent ones would be perfect.

The files and detailed instructions for assembling and setting up are available at github.