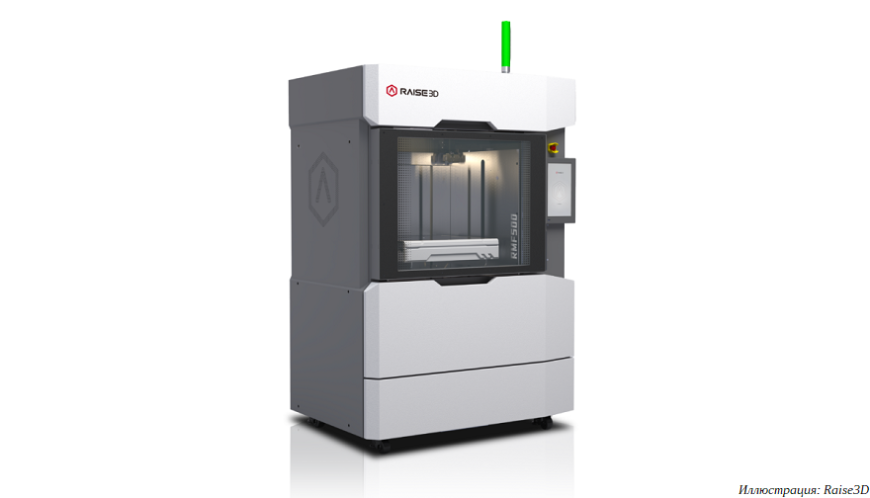

Raise3D is going to release an industrial 3D printer with a build volume of 500 x 500 x 500 mm, which is designed to work with carbon- and glass-filled polymer filaments.

The RMF500 3D printer is engineered with a focus on small-scale additive manufacturing of functional components, including large-sized ones, with high speed and repeatability. The system uses an IDEX kinematic scheme with independent positioning of two extruders along the X-axis, which allows not only working with two materials at once (for example, main and support) but also increasing productivity by building two identical or mirror models (same as with the Raise3D E2).

The mechanics are built on linear motors with positioning accuracy of up to 0.001 mm in the X- and Y-axes and 0.0009765 mm in the Z-axis.The pint speed supposedly reaches 300 mm/s, with accelerations of up to 2g and the maximum positioning speed of 1000 mm/s.

It seems like the new system will work exclusively with proprietary filaments. So far, available is a pair of consumables, namely, carbon-filled polyamide-12 under the name PA12 CF and a support material, which can be separated without the use of solvents. In the future, the range of compatible materials is planned to be replenished with carbon-filled filaments based on polyethylene terephthalate (PET), polyphthalamide (PPA), and polyphenyl sulfide (PPS), as well as a glass-filled version of polyphthalamide. Consumables are offered in cartridges weighing up to 2.5 kg. The filament compartment holds four spools — two for main and two for support material, with automatic switching from an empty bobbin to a full one.

Since the equipment is designed to work with composite materials characterized by low thermal shrinkage, a heated chamber is not provided, although the system features a heated plate with a maximum temp of 110 °C. The hotends can heat up to 330 °С. Due to the high abrasiveness of carbon- and glass-filled composites, wear-resistant carborundum nozzles are employed.