The ITMO Accelerator continues to empower entrepreneurs. We’ve already covered some of its most successful graduates — the Laeneco staethoscope and the GoROBO robotics club. Today we’ll be discussing Hamstand — a modular hub that simplifies the process of mobile app testing. Let’s talk about how it came to be, why it’s a welcome addition to many developers’ toolkits, and what awaits the project in the near future.

Modern app testing comes with a number of logistical issues. Developers have to account for at least a dozen OS/device combinations, which means keeping track of far too much hardware. Phones get lost, batteries get drained, and valuable time gets wasted on the setup instead of actual work. Smaller businesses often tackle this problem with spreadsheets and dedicated Slack channels, but this approach doesn’t scale well.

Larger teams build custom storage solutions, which are often ugly and space-consuming.

Hamstand is an attempt to solve this issue once and for all. It goes an extra mile, storing, charging, and keeping track of your mobile devices without compromising on space, aesthetics, or user experience.

The team entered our accelerator during the prototyping stage. By that time they were already fine-tuning their PCBs, integrating them into the case, and working on the software.

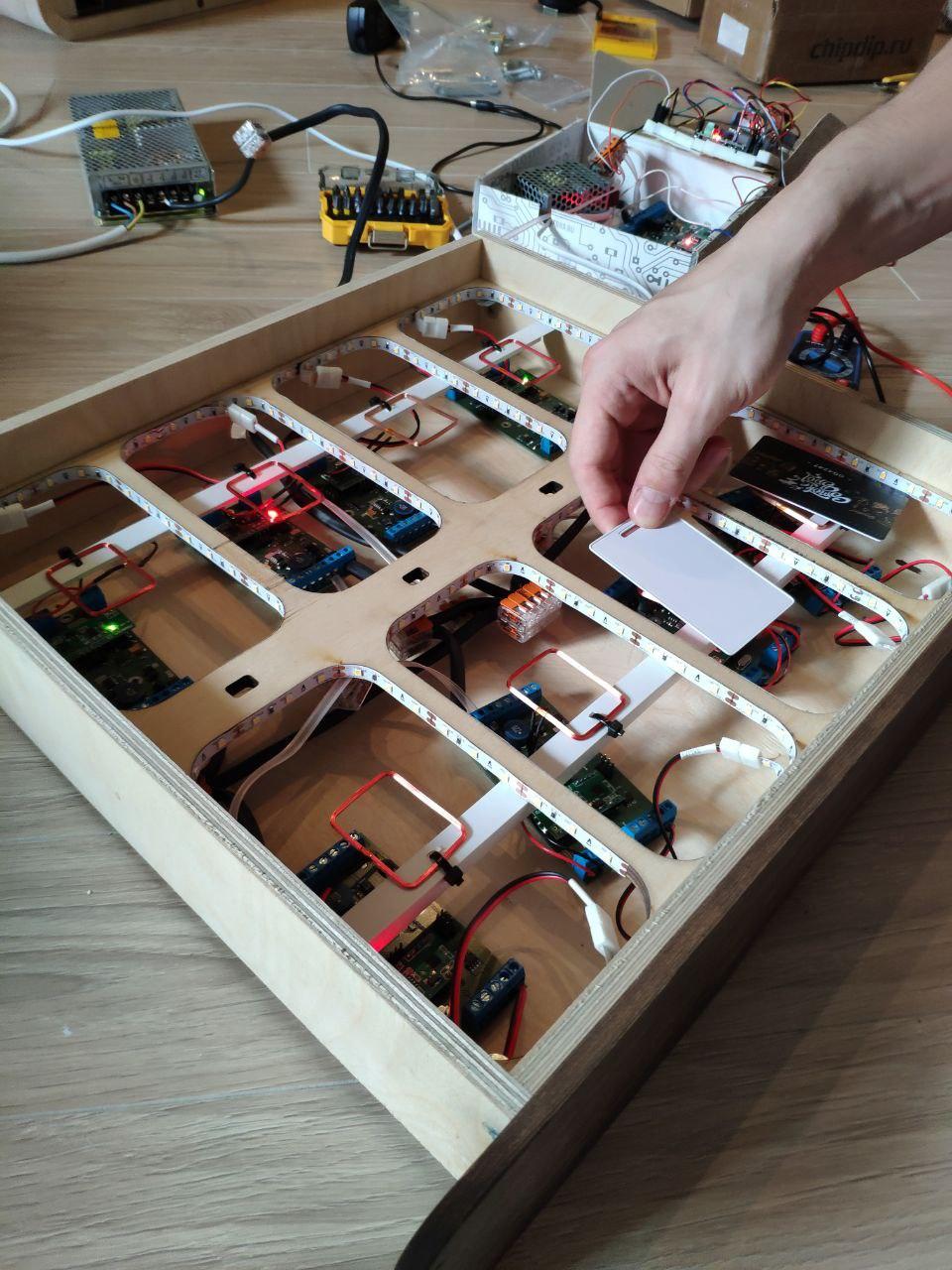

Hamstand is a wooden storage cabinet with a twist. Each of its drawers features custom PCBs with RFID-tracking capabilities. Depending on the configuration, you can house up to eight devices per drawer. All drawers are outfitted with backlighting and a sturdy lock. The cabinet comes with a wooden stand for the iPad that acts as the control unit, as well as an RFID sensor that scans employee cards for authorization. You can enhance the security of the setup by incorporating face recognition technology.

After your gadgets’ RFID tags are added to the system, it starts keeping track of their status. A separate server-side application is necessary to use multiple Hamstand units at once, or to connect them to your employee database. If you’d rather customise the system, you can do it using the API.

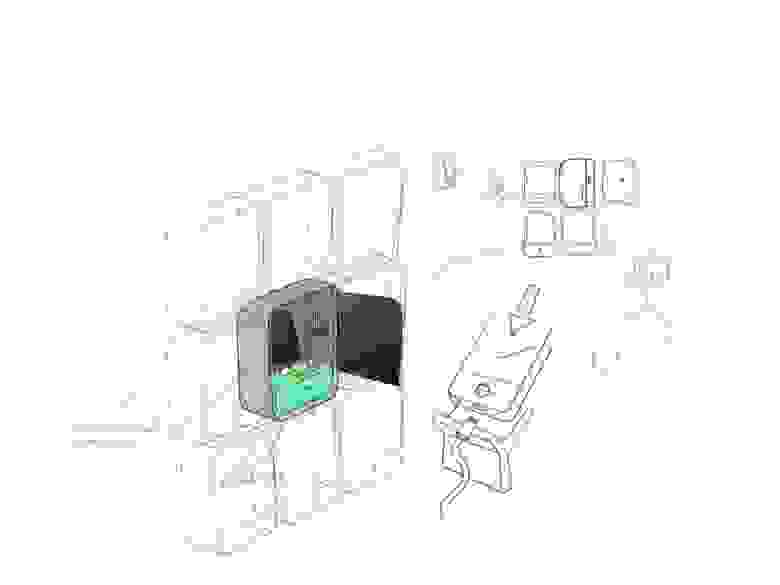

An early sketch of the product

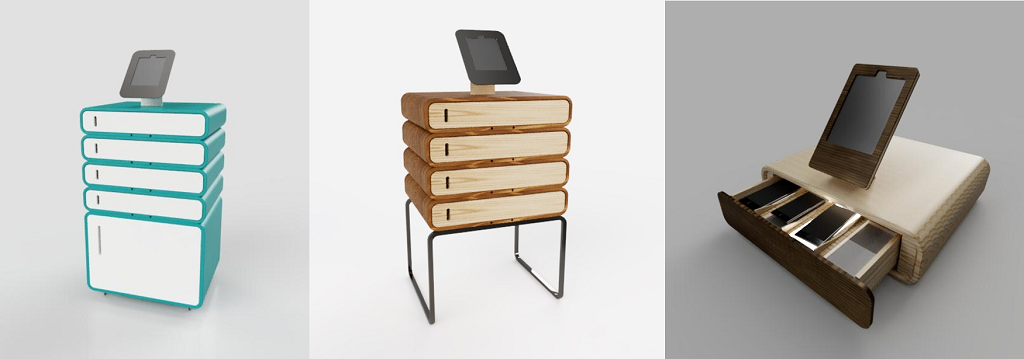

Early 3D mockups (left and centre), one of the later iterations (right).

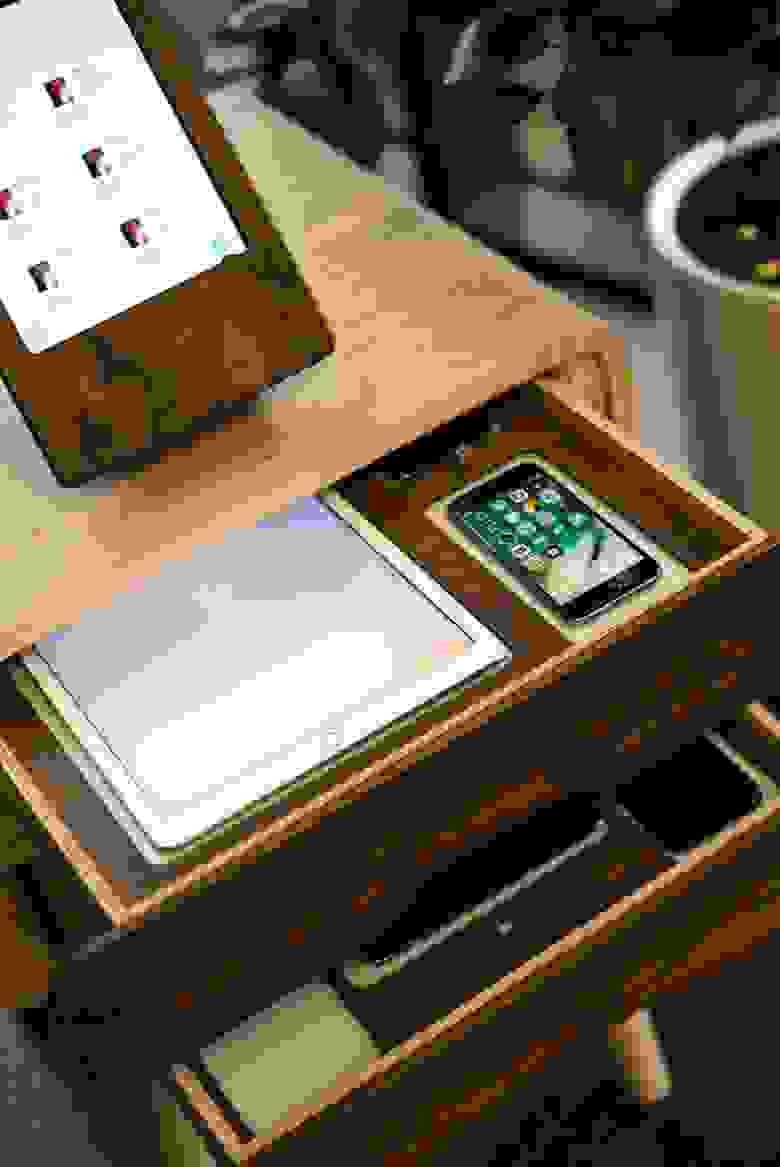

A wooden prototype

The end result

Aesthetics were of utmost importance. If they were to sell Hamstand to IT companies, it had to look the part in upscale office environments. The team spent a lot of time looking for subcontracters who could deliver the quality. The wooden look makes it stand out. This material is rarely used for enterprise IT solutions.

The first batch of PCBs turned out badly. RFID antennae generated significant electromagnetic interference.

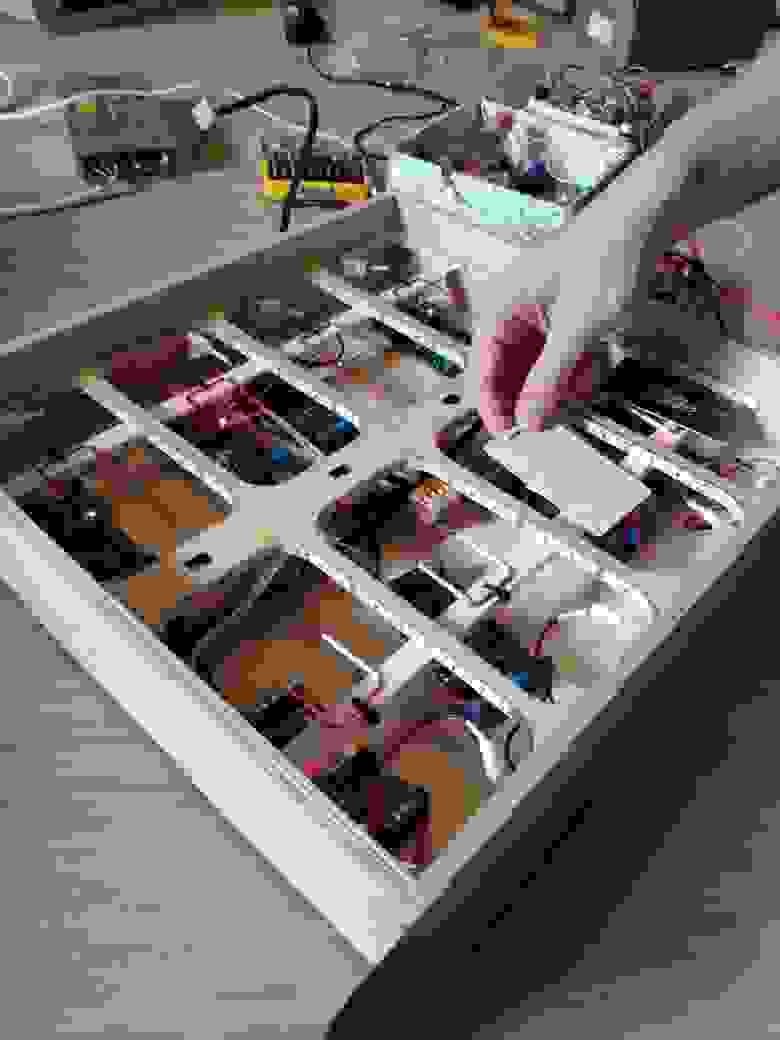

The contents of an early prototype drawer

Failed attempt to get rid of RFID interference with a layer of alluminium foil

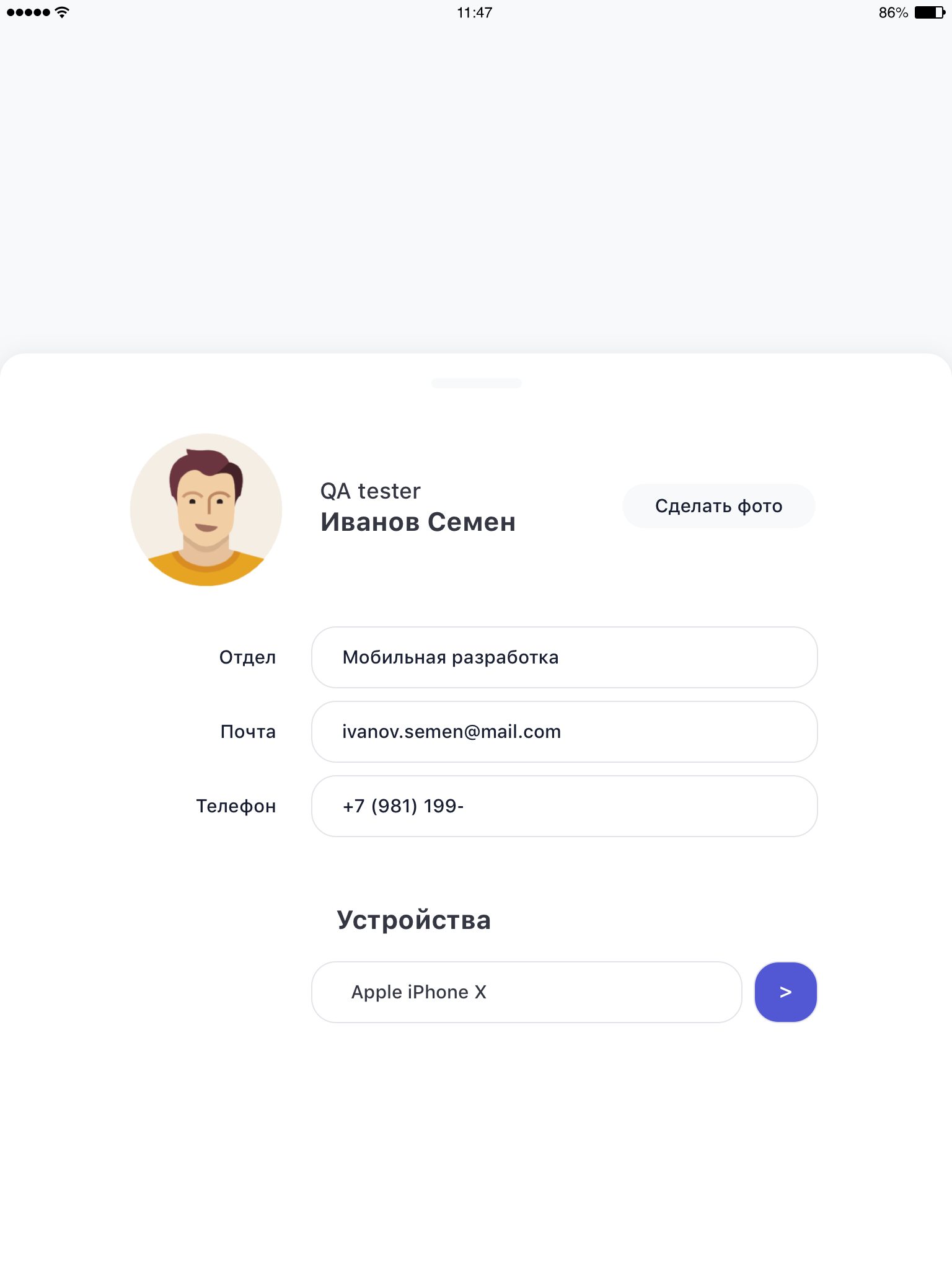

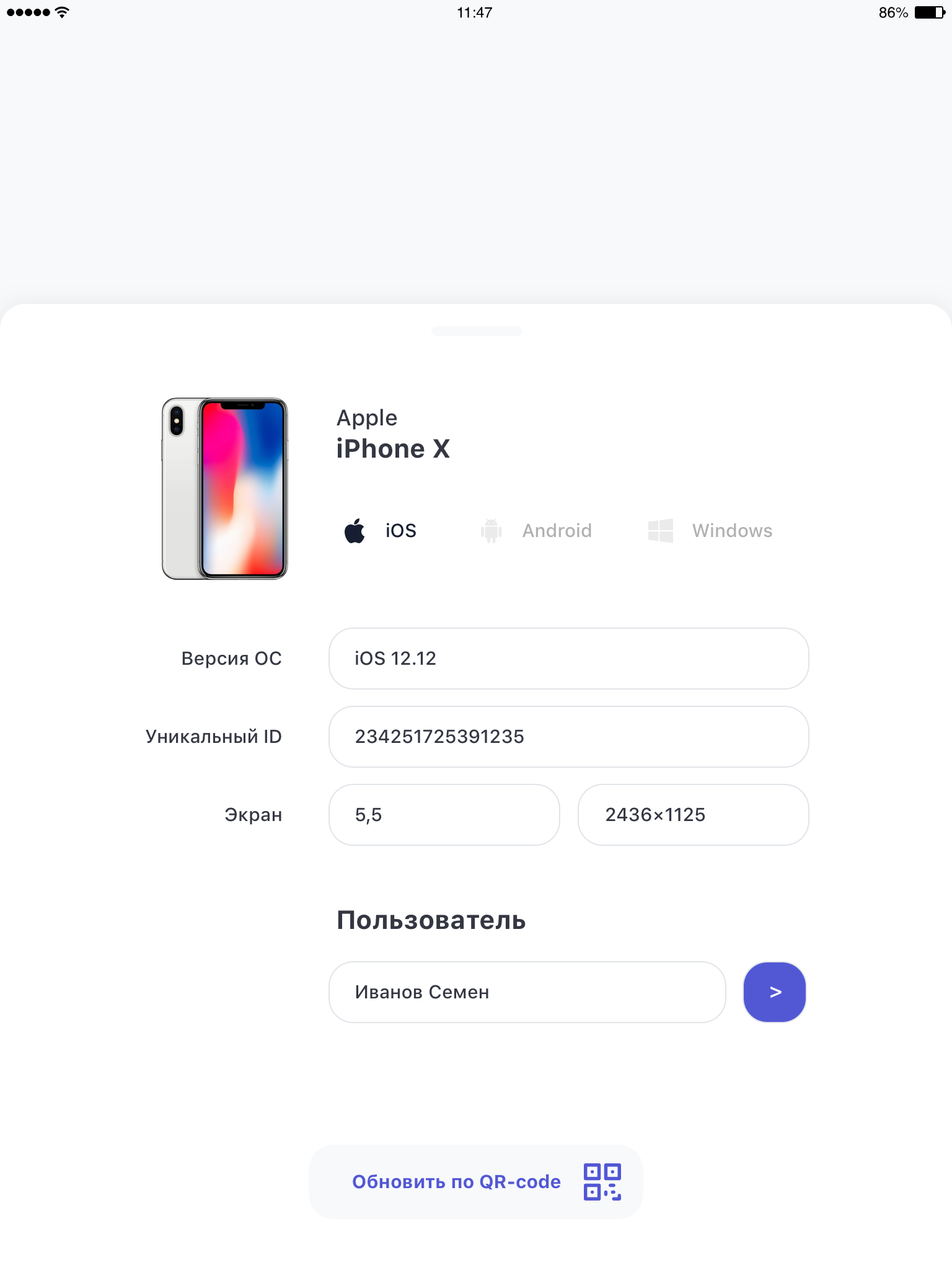

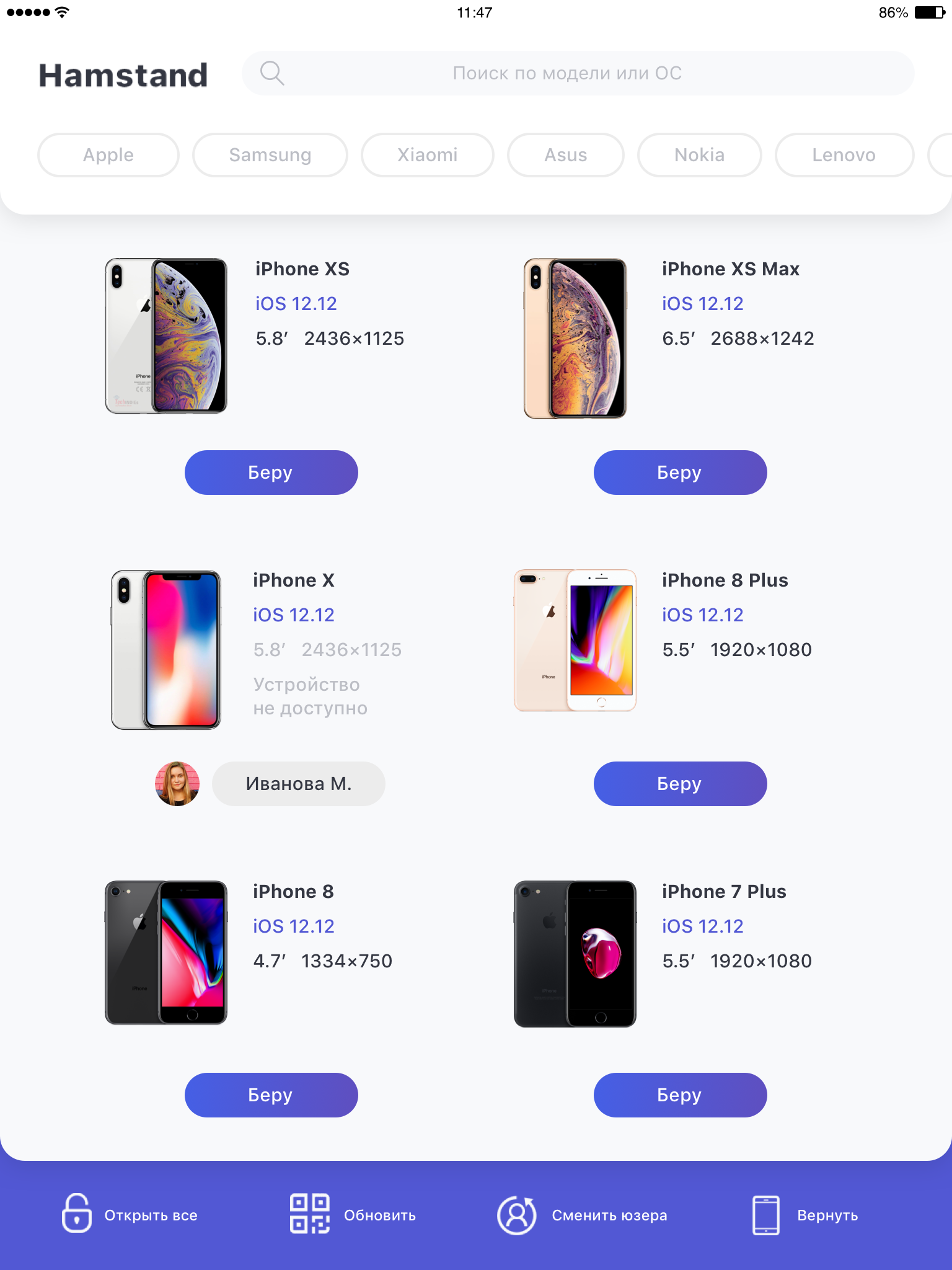

To this day, the electrical components of the Hamstand are being continously improved to save space and increase efficiency. Control unit software also changed during the prototyping process. The team tried a bunch of various UI and UX approaches, ultimately settling on this elegant and easy-to-use interface:

The final, serial design of the PCB

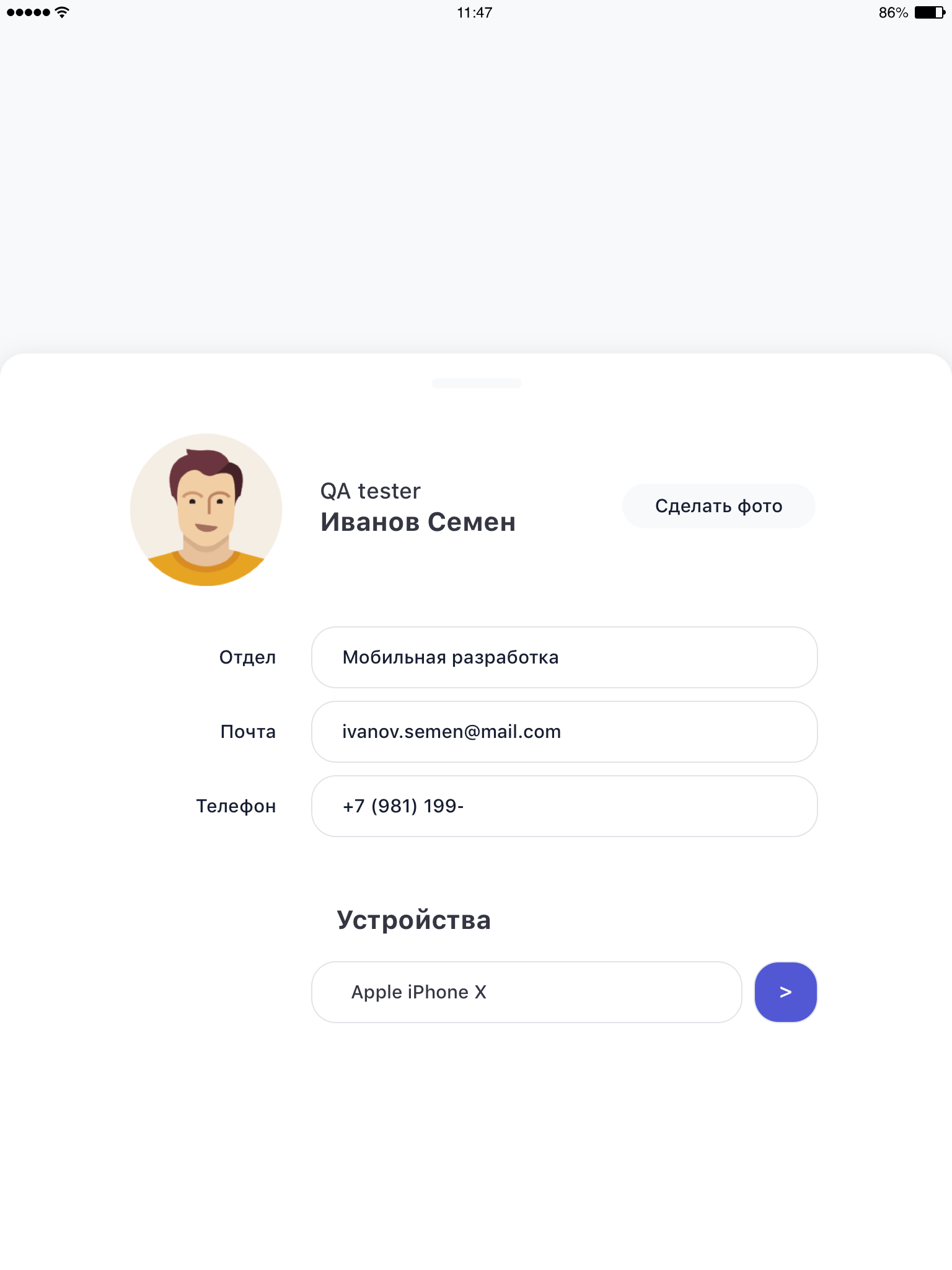

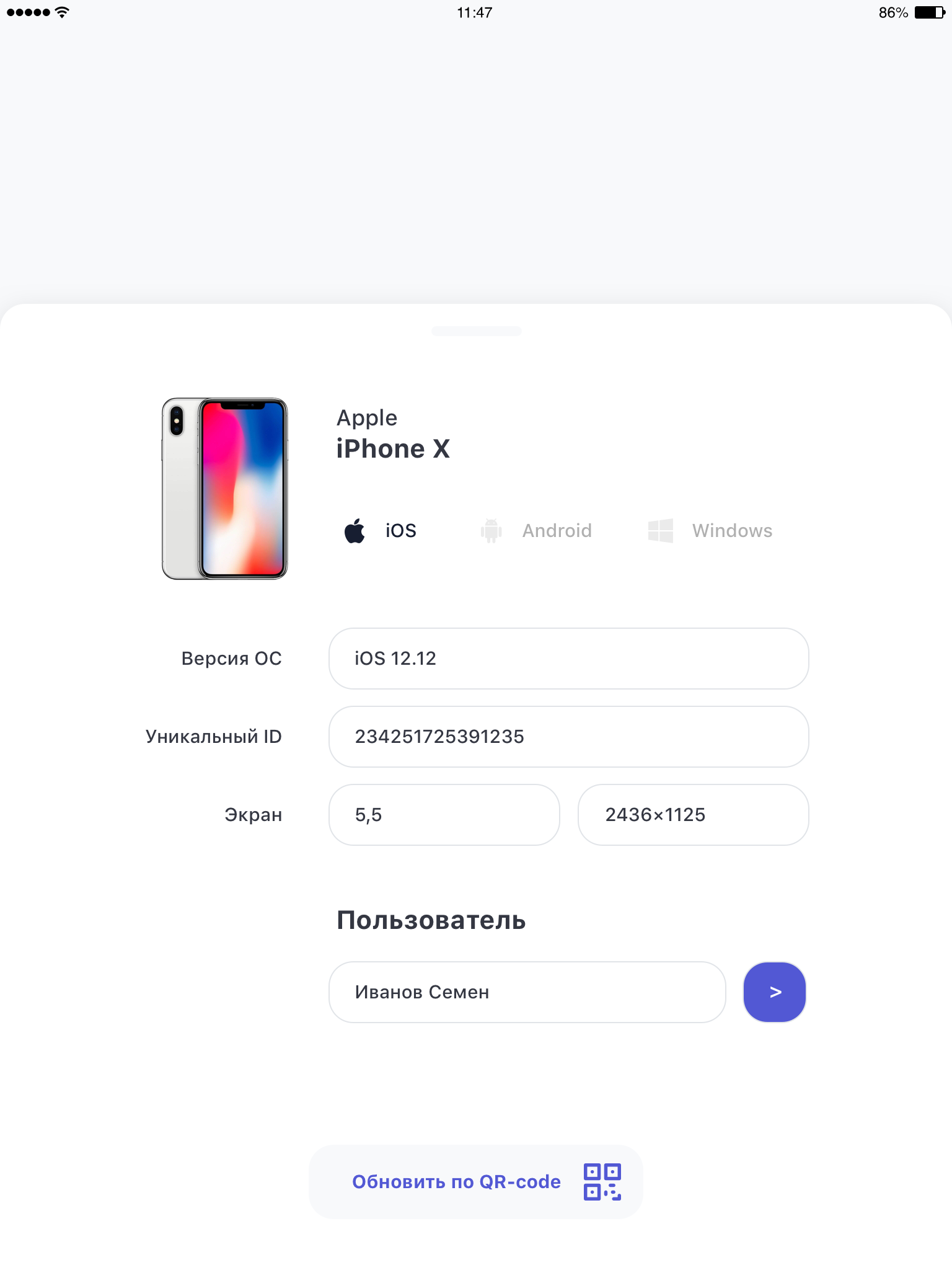

The main UI of the control unit

The user view and the device view

Hamstand has already begun testing their product “in the wild”, at the offices of a large Russian developer that wishes to remain anonymous. Over the course of these tests, the team discovered that the drawers were developing cracks in arid conditions. All the new units now come with a protective coating that prevents this from happening. Company employees also took issue with the cabinet’s weight: the 40+ device, 6-drawer configuration was simply too heavy. As a result, the cabinet was redesigned and is now 35% lighter.

The Hamstand team at the St. Petersburg International Innovation Forum

Right now the team is actively looking for new customers at tech conferences and on social media. Lamoda — the Russian e-commerce giant, and Playrix — the game dev company — have expressed interest in their product. And large companies aren’t the only ones taking note. Last year the team received a custom order from a freelance tester, who wanted a smaller version of the product that would double as a monitor stand.

The Hamstand team is developing custom solutions to expand their market reach. Hospitals that use tablets to update their patients’ medical records will benefit from a Hamstand with a built-in disenfecting system. Industrial corporations have expressed interest in a modified version that keeps track of factory workers’ tools.

The Hamstand team consists of just three people: Dmitry Apekhtin, Sergey Glagolev and Oleg Karakyan.

The Hamstand team

Dmitry, the CEO of Hamstand, is a graduate of the ITMO Univerisity’s Optical technology MA program. He’s responsible for the financial wellbeing of the company, the quality of the end product, its software, and design.

Sergey, the CTO of the company, also holds a Master’s degree from ITMO. As a postgrad, he studied robotics and control systems. He is designing both the hardware and the software that makes Hamstand work.

Oleg is a graduate of both the Bauman Moscow State Technical University and the Moscow Polytechnic University. After getting his degree in metalworking, he moved on to study technological entreperneurship. Today he’s the director of growth at Hamstand, responsible for marketing the product and generating sales.

P.S. If you’re interested in Hamstand and want to have a word with the team behind this product, please DM us!

Further reading:

The idea

Modern app testing comes with a number of logistical issues. Developers have to account for at least a dozen OS/device combinations, which means keeping track of far too much hardware. Phones get lost, batteries get drained, and valuable time gets wasted on the setup instead of actual work. Smaller businesses often tackle this problem with spreadsheets and dedicated Slack channels, but this approach doesn’t scale well.

Larger teams build custom storage solutions, which are often ugly and space-consuming.

Hamstand is an attempt to solve this issue once and for all. It goes an extra mile, storing, charging, and keeping track of your mobile devices without compromising on space, aesthetics, or user experience.

The team entered our accelerator during the prototyping stage. By that time they were already fine-tuning their PCBs, integrating them into the case, and working on the software.

“First of all, I want to say that the program was very well organised. The workshops were useful, and there was an active community of entreperneurs at the university. Our mentors helped us promote the product and come closer to selling it. Our main goal was to confirm the hypothesis that the market needs something like Hamstand. We successfully built the prototype and found potential clients”.

— the Hamstand team.

The solution

Hamstand is a wooden storage cabinet with a twist. Each of its drawers features custom PCBs with RFID-tracking capabilities. Depending on the configuration, you can house up to eight devices per drawer. All drawers are outfitted with backlighting and a sturdy lock. The cabinet comes with a wooden stand for the iPad that acts as the control unit, as well as an RFID sensor that scans employee cards for authorization. You can enhance the security of the setup by incorporating face recognition technology.

After your gadgets’ RFID tags are added to the system, it starts keeping track of their status. A separate server-side application is necessary to use multiple Hamstand units at once, or to connect them to your employee database. If you’d rather customise the system, you can do it using the API.

Builing the first prototype

The first Hamstand prototype took about a year to make. The team went over multiple iterations of both the electronics behind the product and its visual design.

An early sketch of the product

Early 3D mockups (left and centre), one of the later iterations (right).

A wooden prototype

The end result

Aesthetics were of utmost importance. If they were to sell Hamstand to IT companies, it had to look the part in upscale office environments. The team spent a lot of time looking for subcontracters who could deliver the quality. The wooden look makes it stand out. This material is rarely used for enterprise IT solutions.

The first batch of PCBs turned out badly. RFID antennae generated significant electromagnetic interference.

The contents of an early prototype drawer

Failed attempt to get rid of RFID interference with a layer of alluminium foil

To this day, the electrical components of the Hamstand are being continously improved to save space and increase efficiency. Control unit software also changed during the prototyping process. The team tried a bunch of various UI and UX approaches, ultimately settling on this elegant and easy-to-use interface:

The final, serial design of the PCB

The main UI of the control unit

The user view and the device view

Future plans

Hamstand has already begun testing their product “in the wild”, at the offices of a large Russian developer that wishes to remain anonymous. Over the course of these tests, the team discovered that the drawers were developing cracks in arid conditions. All the new units now come with a protective coating that prevents this from happening. Company employees also took issue with the cabinet’s weight: the 40+ device, 6-drawer configuration was simply too heavy. As a result, the cabinet was redesigned and is now 35% lighter.

The Hamstand team at the St. Petersburg International Innovation Forum

Right now the team is actively looking for new customers at tech conferences and on social media. Lamoda — the Russian e-commerce giant, and Playrix — the game dev company — have expressed interest in their product. And large companies aren’t the only ones taking note. Last year the team received a custom order from a freelance tester, who wanted a smaller version of the product that would double as a monitor stand.

“According to our estimates, we have around a thousand potential clients in Russia alone. We plan on acquiring at least 10% of this market and using the revenue to establish our presence in the European Union and the United States” — the Hamstand team.

The Hamstand team is developing custom solutions to expand their market reach. Hospitals that use tablets to update their patients’ medical records will benefit from a Hamstand with a built-in disenfecting system. Industrial corporations have expressed interest in a modified version that keeps track of factory workers’ tools.

Meet the team

The Hamstand team consists of just three people: Dmitry Apekhtin, Sergey Glagolev and Oleg Karakyan.

The Hamstand team

Dmitry, the CEO of Hamstand, is a graduate of the ITMO Univerisity’s Optical technology MA program. He’s responsible for the financial wellbeing of the company, the quality of the end product, its software, and design.

“I’ve always been interested in trying new things. Working on Hamstand lets me apply myself in a vareity of exciting areas, including design, engineering, and software development.”

— Dmitry Apekhtin

Sergey, the CTO of the company, also holds a Master’s degree from ITMO. As a postgrad, he studied robotics and control systems. He is designing both the hardware and the software that makes Hamstand work.

“I loved DIY electronics ever since I were a child. I really enjoy examining the inner workings of technological systems. That’s why I studied robotics at ITMO University, and that’s why, during my senior year, I picked up software development. Hamstand was born out of necessity — my then employer experienced issues managing their mobile devices. I asked my friends if we could create a solution to this problem. We weighed our options and took it on. It’s really cool that both my engineering background and my coding experience can come in handy in the process of creating this device.”

— Sergey Glagolev

Oleg is a graduate of both the Bauman Moscow State Technical University and the Moscow Polytechnic University. After getting his degree in metalworking, he moved on to study technological entreperneurship. Today he’s the director of growth at Hamstand, responsible for marketing the product and generating sales.

“Hamastand is my fifth venture, and, given the experience under my belt, I have high hopes for it. I’m very lucky to be a part of this team. We have known each other for a long time, and share the same worldview.”

— Oleg Karakyan

P.S. If you’re interested in Hamstand and want to have a word with the team behind this product, please DM us!

Further reading: