Stavropol-based Russian company Smart Build launched an open contest of small architectural forms. The winning project will be brought to life with an in-house developed constructional 3D printer.

Everything about 3D printers and 3D printing technology

Stavropol-based Russian company Smart Build launched an open contest of small architectural forms. The winning project will be brought to life with an in-house developed constructional 3D printer.

PJSC Power Machines has started to create a model 16-stage compressor and a prototype combustion chamber of the GTE-65.1 gas turbine. The combustion chamber will be manufactured using 3D printing technologies. Inspection can be completed with the use of laser 3D scanning (see examples here).

If you think this is another eco-activists’ project, you are right. In pursuit of the zero emission concept, the Austrian studio EOOS has created the ZUV (Zero-emissions Utility Vehicle) electric tricycle with a 3D printed body made from recycled plastic waste.

The Taiwanese company Phrozen has announced another desktop 8K resin 3D printer. Although the new Sonic Mini 8K will be much inferior to its older brother Sonic Mega 8K in terms of the build volume, it will obviously cost several times cheaper.

Prusa Research with Josef Prusa in charge bought 80% of shares of Czech manufacturer Trilab, as well as got full control over the company. Trilab is known for its delta 3D printers. Does this merging mean that there will be a delta-kinematics 3D printer under the Original Prusa brand?

A turboprop Catalyst is a powertrain of the new single-engine business jet Beechcraft Denali. The Catalyst was developed by General Electric with the extensive usage of 3D printing. Additive technologies helped to unite 855 parts into 12 components.

Russian 3D scanner manufacturer Thor3D launches its new device: the Calibry Mini.

Made for scanning smalled objects, this affordable and lightweight solution, designed to be easy to use, can be a good choice for education and medical fields, as well as arts and museums.

Anna Zevelyov, CEO of Thor3D, mentions that the device will grant the doctors the ability to scan any part of the body and even perform full-body scans. Museums will now be able to capture various collections with art objects of different sizes. She adds that their engineers conducted multiple tests before release that showed impressive results.

According to her, the device will be a great addition to the company’s portfolio, making their Calibry product line even more versatile and compelling.

The jewelry restoration was done with the help of both computer technologies and traditional methods. Wax, clay and bronze were used.

The archeologists restored a jewelry object made in the Iron Age. It was done with the help of digital technologies.

Restoration included scanning of the clay molds that were used for casting bronze in the 1st and 2nd centuries B.C. Original molds found in Cairns, at South Ronaldsay island of Orkney islands, Scotland, were too fragile to use for jewelry.

Ben Price, a PhD student at the University of the Highlands and Islands, department of Archeology. Around 80 fragments of clay molds were found during the recent excavations of a broch dating back to the Iron Age in Cairns.

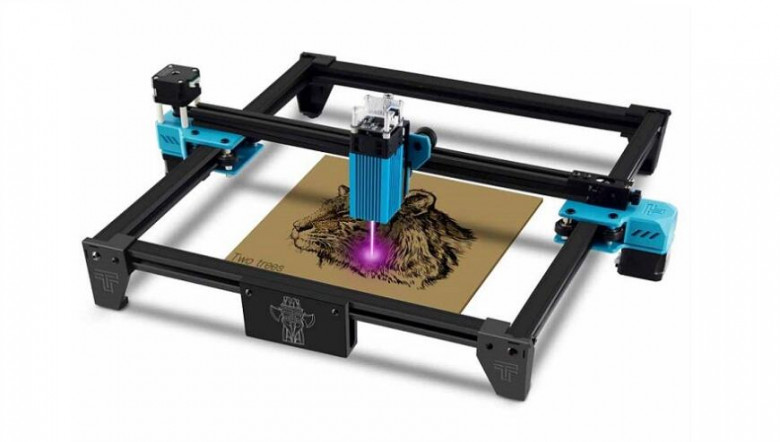

Today, we will talk about a useful tool in the workshop of any maker, a good addition to carpentry and additive equipment, which makes it possible to process the surfaces of various materials — the engraving and cutting machine TwoTrees TT-5.5S with a powerful diode laser.

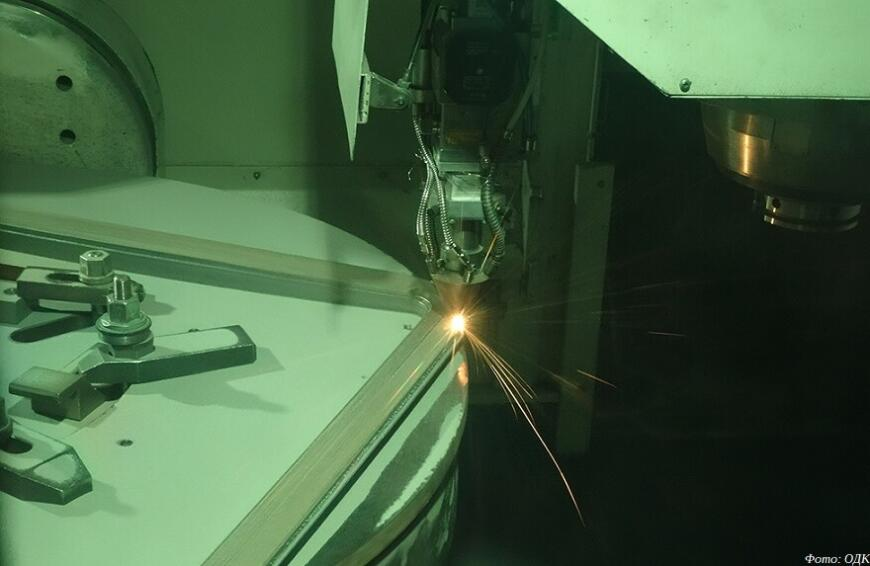

Research Institute of Technology and Organization of Engine Production (NIID, a part of United Engine Corporation, UEC, of Rostec) is continuing the research focused on using additive manufacturing technologies for aircraft engine production with the help of metal 3D printing. The hybrid manufacturing system was launched in 2020 and so far it produced 11 full-size billet engine parts.

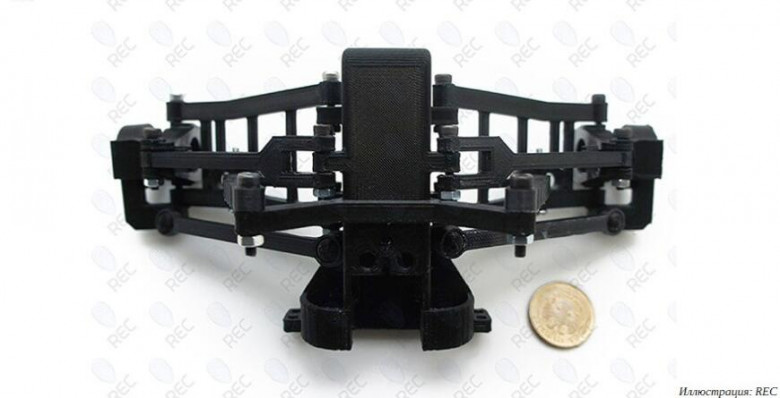

The management of a Russian company REC (that’s been developing and manufacturing 3D printing materials for nine years) thinks that the relevance of the additive manufacturing industry will only continue to grow as long as the market will become even more aware of the abilities of the tech.

Porsche invested money in a German startup called Isar Aerospace that is working on a lightweight launch vehicle with 3D printed parts, including key components of power plants. The initial launch is planned for 2022.

In the past, FDM 3D printing solutions have been primarily used for surgical planning. The added benefit is one can perform surgical planning digitally in preparation for surgical procedures, create mock up operations physically with the usage of trustworthy full-scale printed parts and test implants prior to inserting them into the body.

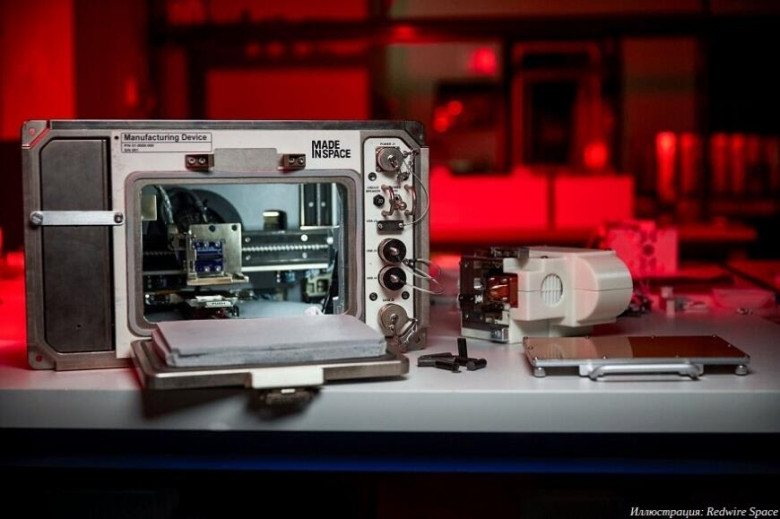

Cygnus NG-16 was recently launched into space. It’s an iSS resupply spacecraft that brings materials and equipment needed for 3D printing with lunar regolith simulant to International Space Station.

The list of materials for additive manufacturing devices Studio System 2 by Desktop Metal now includes a filament filled with titanium alloy Ti-6Al-4V (Ti64), a new step in the field of metal 3D printing.

The world of education is constantly evolving, and one of the most significant recent advancements is the integration of 3D printing. This revolutionary technology, which allows for the creation of three-dimensional objects from digital models, is changing the way educators teach and students learn. At its core, 3D printing involves layer-by-layer construction of objects, enabling the production of complex designs that were previously impossible or too expensive to build.

The All-Russian Institute of Aviation Materials (VIAM) showed its own developments in the field of additive technologies, including a series of small-sized gas-turbine engines MGTD-10, MGTD-20 and MGTD-150.

Reverse engineering of such parts can be done using 3D scanners. You can see some examples and sample deviations here.

We have previously written about how the Raise3D Pro2 is used for printing surgical guides. In this article, we will talk about intervertebral cages developed and patented by the Pozvonoq startup of the North-West Technology Transfer Center and the Russian manufacturing company Ortoinvest, which specializes in the development and production of power equipment and implants for traumatology and orthopedics.

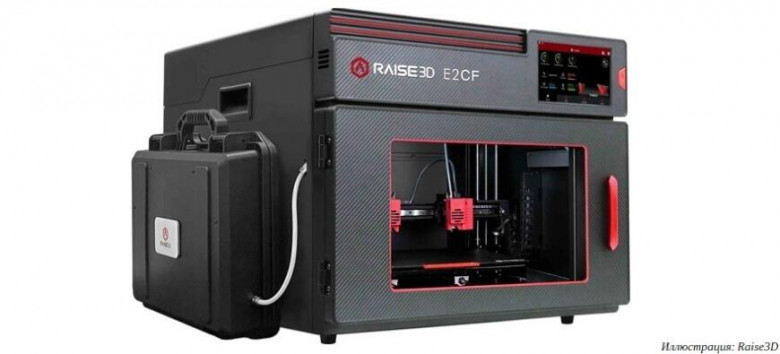

Raise3D is preparing to receive pre-orders for E2CF — a version of its desktop additive system E2 that is able to print using carbon-fiber-reinforced polymers. The device is optimized for working with carbon-filled filaments.

Previously, Raise3D was primarily known for its large-format series such as the Raise3D Pro2 Plus (build volume: 305 x 305 x 605 mm), but the manufacturer is certainly planning to expand in the industrial segment with their focus on engineering-grade materials.

Hello! This article will cover 3D printer manufacturer Modix and its professional large-scale 3D printers. The review will include the history of the brand, its products, their functions and possible applications.