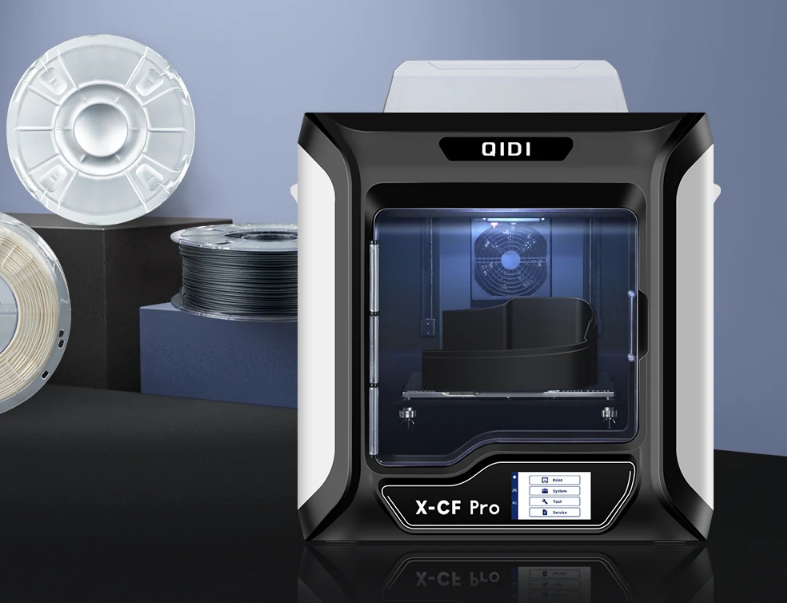

The Zhejiang-based company QIDI has launched a brand new industrial-grade FFF machine designed for printing nylon and carbon fiber-reinforced filaments.

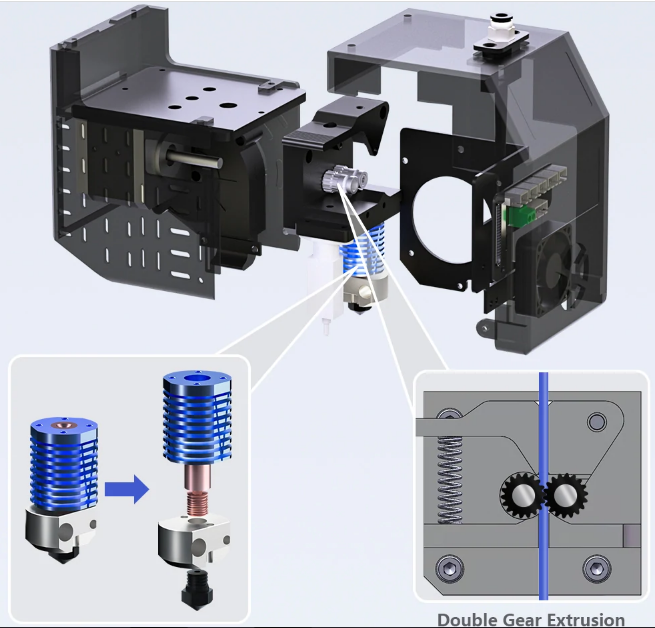

The system features a build volume of 300 x 250 x 300 mm and comes with two replaceable extruders — a high-speed option for printing with ordinary plastics like PLA, ABS and PETG, and a special dual-gear extrusion system that uses high-temperature allow material for working with carbon fiber and nylon. This high-end extruder can reach temperatures of up to 350 °C, ensuring high accuracy of outputs and long service life of the mechanism.

The QIDI Tech X-CF Pro is equipped with a new smart automatic bed leveling using a BLTouch laser module. The build plate has a surface made of PEI, which makes for great adhesion and helps avoid problems such as warping. Among other bells and whistles of the device are a filament runout sensor, wide connectivity including Wi-Fi, and a sensitive 5-inch HD touchscreen.

The printer is recommended to be used with the upgraded QIDI software that makes printing with professional filaments convenient and effective, providing a wide range of parameters to be adjusted for optimal performance. The main board of the X-CF Pro uses the ARM Cortex-M4 processor core and silent TMC2209 driver chip.

In addition, QIDI offers a line of new professional filaments to get the most out of industrial-grade printing.

Tech specs

Technology: FDM/FFF

Build volume: 300 x 250 x 300 mm

Print accuracy: 0.05–0.2 mm

Nozzle size: 0.4 mm

Max. hotend temperature: 350 °C

Supported materials: PA12-CF, PLA, ABS, TPU, PETG, Nylon, PC

Print speed: 60 mm/s

Connectivity: Wi-Fi, LAN, USB flash drive

Software: QidiPrint, Cura, Simplify3D

Dimensions: 610 x 515 x 678 mm

Weight: 32.5 kg