Manufacturing jewelry with the help of the EinScan Pro 2X 2020 3D scanner

Many people think that 3D scanning is mainly used in industrial settings: for metrological and reverse-engineering purposes.

And just a few years ago, these two fields were the only ones where 3D scanning was used. But times changed, and scanners started being utilized in other sectors. Modern devices, such as the EinScan Pro 2X 2020 by Shining 3D, have proved that 3D digitizing can be implemented for many different things, ranging from small pet projects to professional reverse-engineering. The EinScan Pro 2X 3D scanners helped new users integrate 3D scanning and 3D design solutions into manufacturing for a lower price tag. This is why we can now see even more creative use cases for the technology.

Now that the modern 3D scanners are more accessible and easier to use and maintain, some business segments started to integrate 3D scanning solutions into their production cycle (they could not before due to higher entry prices).

Schnider & Hammer AG use 3D scanning actively and in this article we will cover one unusual project that was brought to life with the help of the EinScan Pro 2X 3D scanner.

EinScan Pro 2X 2020 Technical Specifications

Accuracy | Up to 0.04 mm |

Connectivity | USB |

Display | No |

Manufacturer | Shining 3D |

Manufacturer country | China |

Weight kg | 1.13 kg |

Technology | Structured light |

Acquisition speed | Up to 3,000,000 points/s |

Computer Requirements (Recommended) | Graphics card: NVIDIA GTX1060 and higher; video memory: >4G, processor: I7-8700, memory: 32G; interface: high-speed USB 3.0 |

Computer Requirements (Required) | Graphics card: Quadro card P1000 and above or NVIDIA GTX660 and higher; processor: Intel (R) xeon E3-1230, Intel (R) I5-3470, Intel (R) I7-3770; interface: high-speed USB 3.0; memory: 8G |

Max. resolution | Up to 0.2 mm |

Output formats | OBJ , STL , ASC , PLY , P3, 3MF |

Rotating table | Yes (with industrial pack add-on) |

Scan volume max | 250 × 200 mm |

Texture / Colors | Yes (with color pack add-on) |

Scan volume min | 150 × 120 mm |

About Schnider & Hammer AG

Schnider & Hammer was founded in 1993, and the company specializes in traditional manufacturing of jewelry. Despite working with the classical approaches for more than 25 years, the company was always interested in modern technologies and their integration.

The company worked with 3D design solutions and digital manufacturing systems right from the start. They used it to supply high-quality products to the market in short times. The masters make peculiar and beautiful jewelry, such as an impressive bracelet collection named Weissenstein.

One of the brand’s latest ideas was to make jewelry that resemble nature and reproduce its beauty. The patterns of wood and stone surfaces are incredible and awe-inspiring. But reproducing such patterns using traditional jewelry production methods is a difficult task. The forms and shapes common in nature are not easy to imitate in a workshop.

Finding a 3D scanner to meet the requirements

After long consideration, the company decided to buy a 3D scanner. The experts knew about the technology and were interested. They were aware that a professional 3D scanner could solve the problem of nature’s pattern reproduction. There are many different scanners available at the market but not all of them would meet the company’s specific expectations and requirements. The EinScan Pro 2X 2020 was the solution they were searching for. It was a professional 3D scanner that managed to be a relatively affordable device. Moreover, it’s a very convenient solution for less experienced users, so it can be utilized in various fields, thanks to its versatility.

Using EinScan Pro 2X 2020 in the professional setting

The greatest caveat was that the models were offered by nature itself. This means that many of them were located outside in the bright daylight. All of the 3D scanners that use optics and cameras use their own light sources to capture an object and get a 3D version of it. That means that working outside is a big problem in itself for the vast majority of the scanners. The company also needed to find a way to find a power source for the device.

The EinScan Pro 2X is compatible with a battery so the workers just went outside with the laptops and scanned the needed objects provided there was enough shade on the objects. The surface area of the trees meet that requirement, since the leaves casted enough shade for the scanner to work efficiently.

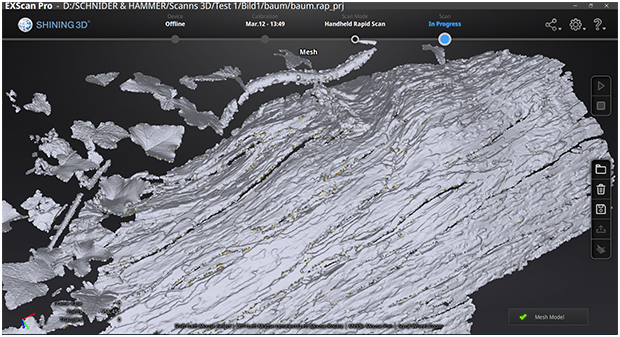

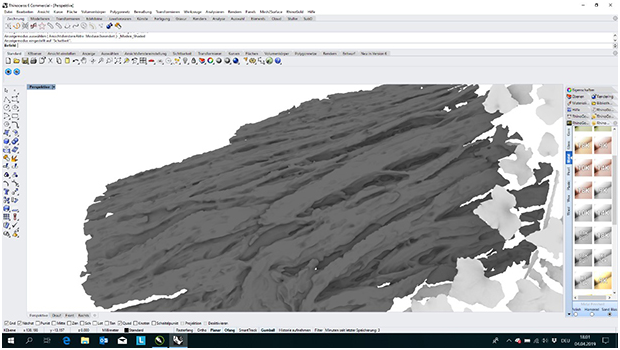

Digitizing is quick, so in just a few minutes one could export the file from the EinScan software solution into professional 3D modeling programs. A resulting digital model would have a high level of detail, providing even slight imperfections being visible on the surface of a 3D tree. This level of detail can only be produced by nature itself, and that’s exactly what Schnider & Hammer were trying to capture. The scanning result would completely reproduce an original but can also be easily changed or edited with the help of the CAD programs.

Jewelry and other things inspired by nature would often struggle to maintain the beauty and energy of the original. 3D scanning provides a safe way to reproduce it in digital solutions. The EinScan Pro 2X makes it possible to use the 3D digitizing technology without problems and large costs.

A final 3D model that is easy to use features the needed shape of a future jewelry object. This time the company’s artists decided to turn a tree surface into a ring. But such models can be used for various shapes and sizes. The final part can be produced using traditional methods and keeping high quality.

Conclusion

The EinScan Pro 2X 2020 by Shining 3D managed to cut the costs that would be otherwise spent on a more expensive 3D scanning solution. The device helped the company to avoid large spendings and use the design solution for its own purposes. 3D scanning can now be used in more creative industries. The market segments where the usage of traditional manufacturing solutions is very common, are also integrating 3D scanning to optimize their workflows. 3D scanning was never this simple.