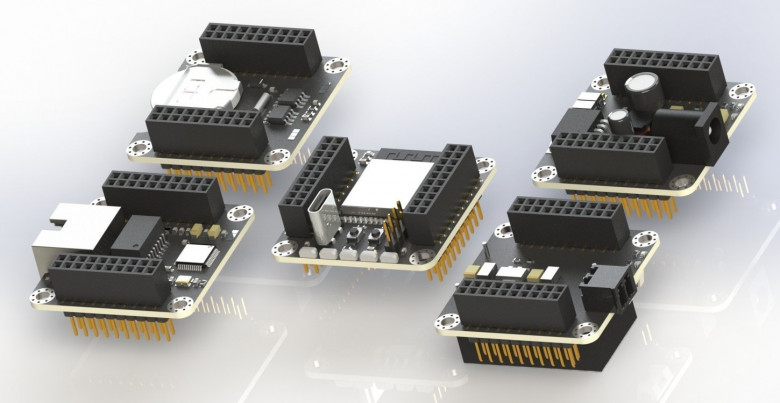

Building set for embedded developers

In this article I will talk about my attempt to create flexible, compact and beautiful modular prototyping framework

In this article I will talk about my attempt to create flexible, compact and beautiful modular prototyping framework

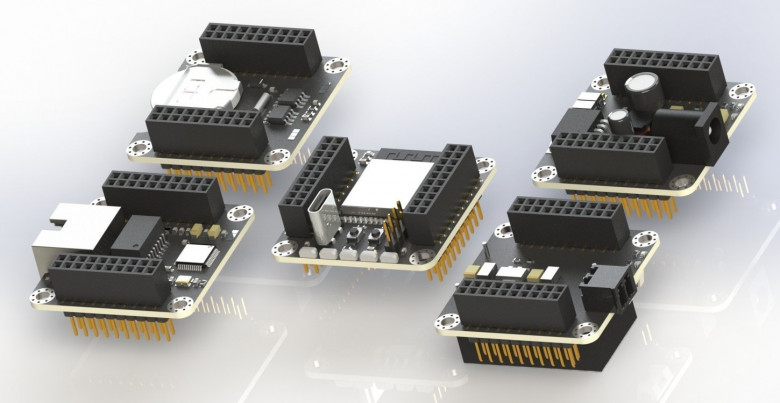

In this article, I want to describe my experience of paying off technical debt on our project in the form of a guide. In this guide, I will highlight some of the most common cases of technical debt and suggest methods for solving them. Since this is a rather extensive topic, I will recommend several books for study, because I do not see it possible to talk about everything within the framework of this article. Everything described applies to the BackEnd part, but it may be suitable for other developers. I would be glad if you share your experience on this topic in the comments.

Image Credit: amazonspreview.com

Cricket in India is more than just a game and for most of it is a matter of pride and unity. As we all have grown up playing cricket and everyone knows all about its rules and techniques that are quite interesting. Over the last few years, the Indian premier league is the latest and most renowned version of cricket that has 20 overs. Within a short span of time, it has become one of the best sports traditions in India.

Day by day the fanbase of IPL is increasing and there are many IPL live streaming cricket apps, where you can enjoy IPL matches.

In this article, we will count everything you should know about IPL 2023.

IPL 2023

The IPL is a professional T20 cricket league in India that was first begun in 2007 by the Board of control for cricket in India, and in 2023, it will be the 16th season of the premier league. Basically, it is contested by ten teams and annually it is held in summer across India between March to May.

So, here is the team of IPL 2023.

IPL 2023 Teams

Here is the list of the total teams of IPL 2023 and its players.

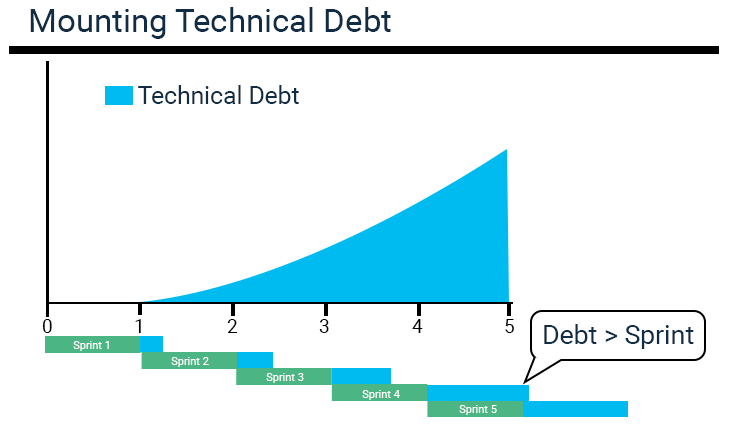

High Dynamic Range (HDR) allows for a wider range of colours and brightness levels. This technology works on displays that support HDR format. Nowadays web advantage of display gamuts such as Display P3 and Rec. 2020, which can display a much larger color space than traditional sRGB displays. It is 50% more colours.

CSS is ready to fix it (at least for Apple users). Find colour gamuts comparison, code examples and device support overview below.

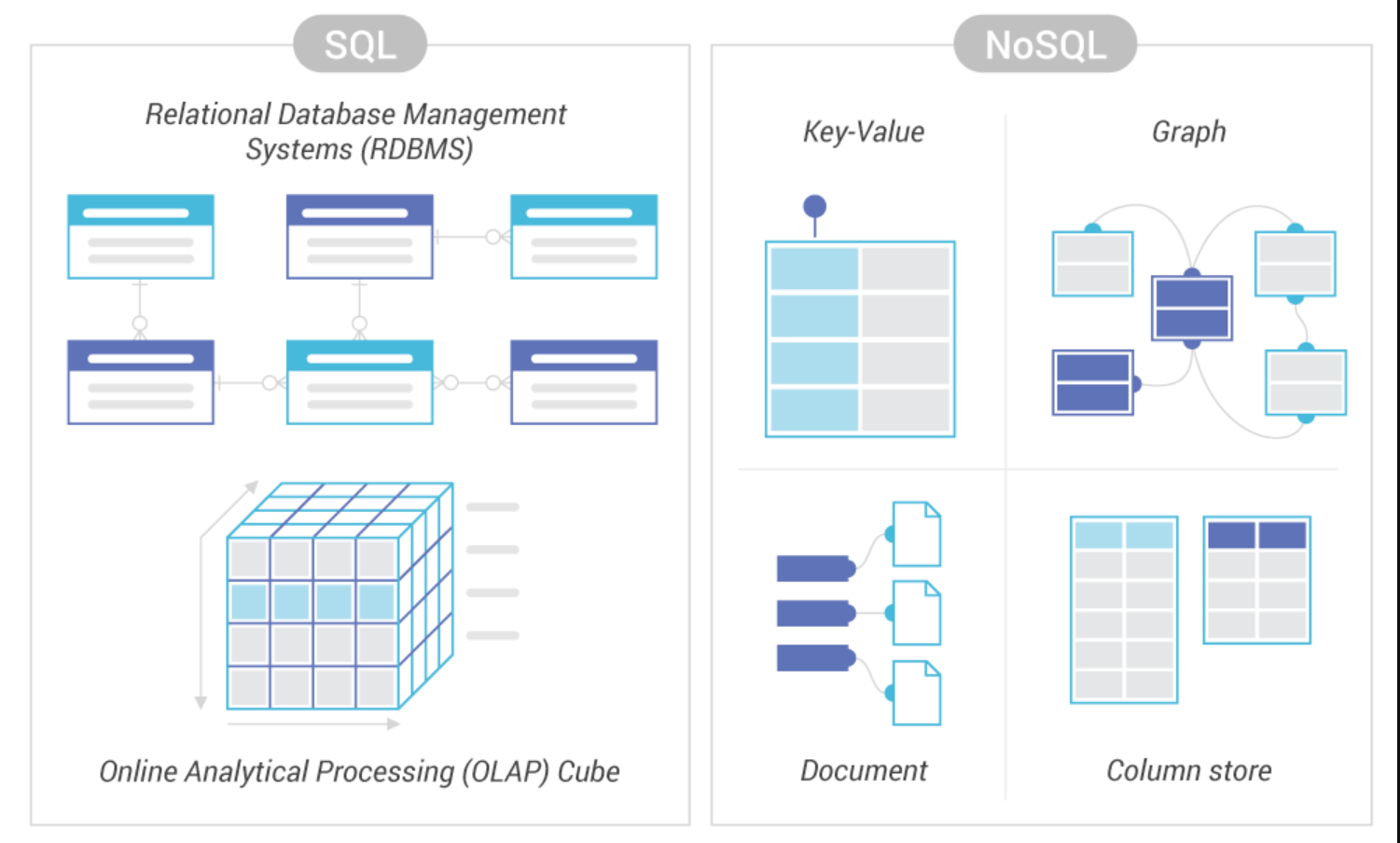

This is a series of articles dedicated to the optimal choice between different systems on a real project or an architectural interview.

This topic seemed relevant to me because such tasks can be encountered both at work and at an interview for System Design Interview and you will have to choose between these two types of DBMS. I plunged into this issue and will tell you what and how. What is better in each case, what are the advantages and disadvantages of these systems and which one to choose, I will show with several examples at the end of the article.

SQL or NoSQL?

Online sports betting is a vertical of the gambling industry that has witnessed a massive surge in recent years. It is a great source of entertainment and thrill for online punters and bettors. Moreover, it also provides monetary benefits that are enough to entice the average layman. This is one of the most prominent reasons why people are gravitating towards these online sports betting platforms.

Additionally, the growing popularity of these platforms is urging sports betting software development companies to innovate and upgrade their platforms to cater to the growing needs of the user base. This is where Artificial Intelligence comes into the equation, AI has been at the forefront of innovations and development and has been offering users an enhanced user experience across multiple platforms.

Artificial Intelligence technology has allowed Sports betting platforms to evolve with time and streamline their operations for better efficiency and enhanced productivity. This is why sports betting platforms all over the world are adopting this technology to offer better features and functionality to users and also increase their productivity and revenue.

In this article, we will highlight how Artificial Intelligence has influenced the sports betting industry. So without further delay, let’s get started.

Now that 2022 has come to an end, we would like to share the DDoS attack mitigation and BGP incident statistics for the fourth quarter of the year, which overall saw unprecedented levels of DDoS attack activity across all business sectors.

In 2022, DDoS attacks increased by 73.09% compared to 2021.

Let's take a closer look at the Q4 2022 data.

Video recording of our webinar about dstack and reproducible ML workflows, AVL binary tree operations, Ultralytics YOLOv8, training XGBoost, productionize ML models, introduction to forecasting ensembles, domain expansion of image generators, Muse, X-Decoder, Box2Mask, RoDynRF, AgileAvatar and more.

Unlock the power of Transformer Neural Networks and learn how to build your own GPT-like model from scratch. In this in-depth guide, we will delve into the theory and provide a step-by-step code implementation to help you create your own miniGPT model. The final code is only 400 lines and works on both CPUs as well as on the GPUs. If you want to jump straight to the implementation here is the GitHub repo.

Transformers are revolutionizing the world of artificial intelligence. This simple, but very powerful neural network architecture, introduced in 2017, has quickly become the go-to choice for natural language processing, generative AI, and more. With the help of transformers, we've seen the creation of cutting-edge AI products like BERT, GPT-x, DALL-E, and AlphaFold, which are changing the way we interact with language and solve complex problems like protein folding. And the exciting possibilities don't stop there - transformers are also making waves in the field of computer vision with the advent of Vision Transformers.

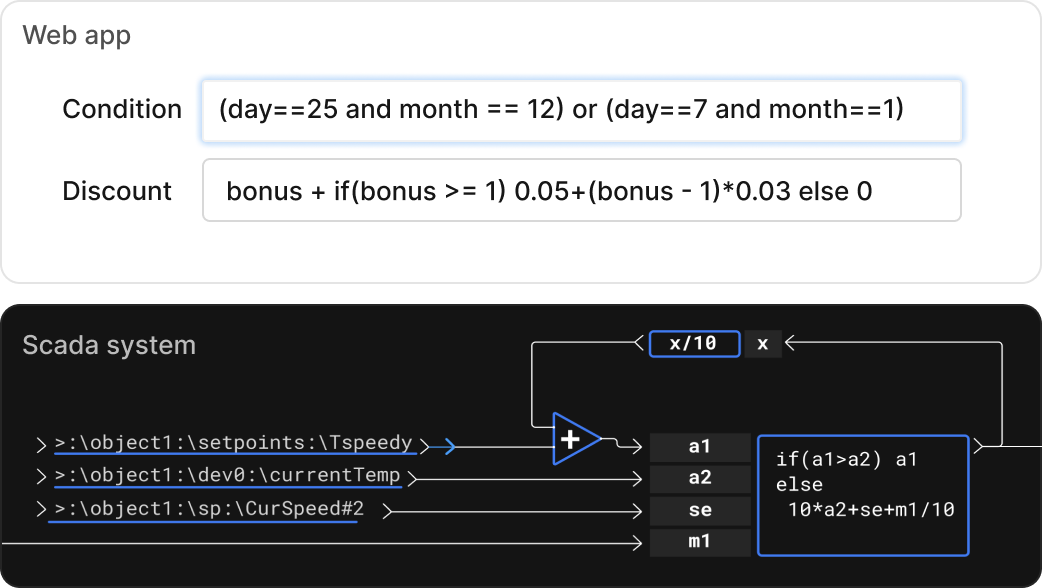

Nfun is an embedded language and expression executor that supports primitive types, arrays, structures and lambda expressions.

Most likely, you have already met tasks that require such a tool, and in this article I want to show examples of its application, its capabilities and why it may be useful to you.

Hello everyone! We've already talked in our blog about how the Positive Hack Days 11 forum had a special Payment Village zone, where anyone could look for vulnerabilities in an online bank, ATMs, and POS terminals. Our competition to find vulnerabilities in an online bank is not new, but in recent years it has been somewhat supplanted by ethical hacking activities for other financial systems. In 2022, we decided to correct this injustice and created a new banking platform, making use of all our years of experience. We asked the participants to find typical banking vulnerabilities and report them to us. In the competition, the participants could play for either the "white hats" (participate in the bug bounty program of an online bank) or for the "black hats" (try to steal as much money from the bank as possible).

Most people assume crypto and NFT are the same but both are different. NFTs are based on blockchain platforms that allow the minting and exchange of cryptocurrencies of a specific type. The basic difference between crypto and NFTs is that two NFTs can not have equal value. Meanwhile one 1 crypto coin will be equal to one coin.

In this article, we will discuss NFT games, like why they are trending and what features and functions are making them more advanced than traditional games. As the demand for NFT based is increasing day by day, then you can also churn this opportunity by developing your own game with the help of a crypto app development company.

Before diving in, let’s know about the blockchain and NFTs.

In this tutorial, we will learn how to select photos in a React Native application using the popular library react-native-image-picker. We will cover setting up a new React Native project, installing the library, getting permissions for the camera and library, and selecting and taking photos.

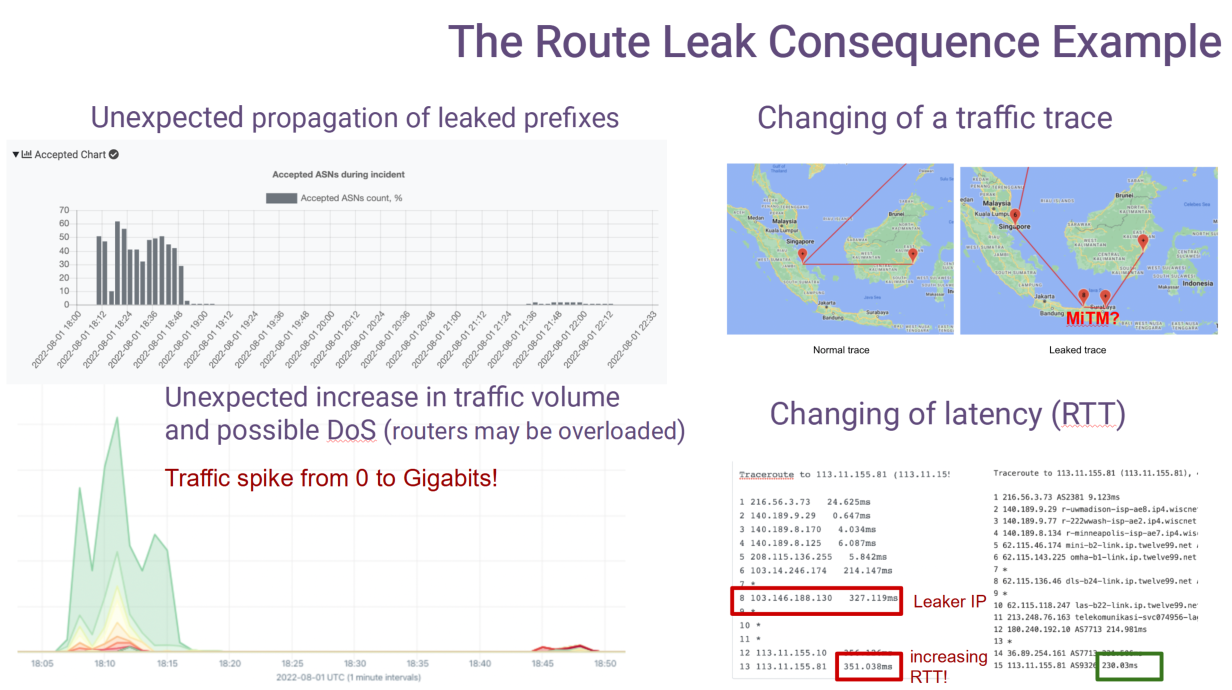

All the credit is due to the RFC’s authors: A. Azimov (Qrator Labs & Yandex), E. Bogomazov (Qrator Labs), R. Bush (IIJ & Arrcus), K. Patel (Arrcus), K. Sriram.

A BGP route leak is an unintentional propagation of BGP prefixes beyond the intended scope that could result in a redirection of traffic through an unintended path that may enable eavesdropping or traffic analysis, and may or may not result in an overload or complete drop (black hole) of the traffic. Route leaks can be accidental or malicious but most often arise from accidental misconfigurations.

From language translation and virtual assistants to self-driving cars and personalized recommendations, AI has been a buzzword for a while now, but it seems that it is only now with the new ChatGPT 3 being released to the public that it is so close to revolutionizing the educational technology field as well. In this article, I would like to give my first impressions, test results, and insights on the new technology.

ChatGPT is a chatbot by OpenAI that can write texts, code, answer questions, and solve various problems. It can even write college essays that, although lacking heart and personal touch, are still pretty good.

It somehow reminds me of the times when distance learning started captivating different fields and what started as a tool for kids with special needs (about 15 years ago, it was a major theme in pedagogical universities, at least) turned into massive online open courses from top universities available to anyone with access to the internet. In corporate learning culture, it went from "e-learning is a cheap and less effective replacement for offline trainings" to being a part of a complicated educational system where we can have the best qualities of offline and online learning for employees.

Right away, serious discussions emerged on the threats to the usage of ChatGPT. Since the beginning of December, many educators have been giving their opinion on its ability to write essays, code, and find correct answers for tests and on the studying culture that will probably need to change.

Hello there! Recently, I had very cool experience at my work. I needed to set tableView with a dynamic header. The information in the header was complete in the initial state, and when the user was scrolling the table, some part in the header was smoothly hiding and the main part remained on the top. Cool, right?

Once every true-linux engineer gets a trouble: there is no any software in his distro or it's built without needed options. I am keen on the phrase: "Only source control gives you freedom".

Of course, you can build this software on your computer without any src-packages, directly (with simplification: configure, make, make install). But it's a non-reproducible solution, also hard for distribution.

The better way is to make distro-aligned package that can be built if needed and that produces lightly distributed binary-packages. It's about debian-source packages(debian,ubuntu,etc), pkgbuild (for arch), ebuild for gentoo, src-rpm for red hat-based, and many others.

I will use cri-o like a specimen.

Before reading the text below I strongly recommend to get familiarized with the official Debian policy manual placed here and debhelper manpage.

Also you will be required to setup some variables like DEBMAIL and DEBFULLNAME for proper data in changelog and other places.

We continue to follow the news of the upcoming PostgreSQL 16. The third CommitFest concluded in early December. Let's look at the results.

If you missed the previous CommitFests, check out our reviews: 2022-07, 2022-09.

Here are the patches I want to talk about:

meson: a new source code build system

Documentation: a new chapter on transaction processing

psql: \d+ indicates foreign partitions in a partitioned table

psql: extended query protocol support

Predicate locks on materialized views

Tracking last scan time of indexes and tables

pg_buffercache: a new function pg_buffercache_summary

walsender displays the database name in the process status

Reducing the WAL overhead of freezing tuples

Reduced power consumption when idle

postgres_fdw: batch mode for COPY

Modernizing the GUC infrastructure

Hash index build optimization

MAINTAIN ― a new privilege for table maintenance

SET ROLE: better role change management

Support for file inclusion directives in pg_hba.conf and pg_ident.conf

Regular expressions support in pg_hba.conf

— Glitchy couch! — Anton exclaimed, yet another time crushing down his fingers by heavy coach he and Sergey were pulling for 14 storeys already.

— ‘Glitchy’? — Sergey asked — have you been coder in the past too?

They’ve been working almost a week together, but Sergey would have never suspected he was coder in the past. Lean and muscular Anton did not look the part at all.

— I had to in my student years, — Anton answered, abashed.

— Relax! One of us. Layout, three years and JS for every browser out there, — Sergey perked up, pushed the couch and pressed it a bit forcefully on Anton.

Global corporations became a part of our everyday life for a long time ago, their products often don’t leave an alternative option for users. Either is it exist? This article touches an issue of dominating big companies in certain areas, but also contains a row of useful tips. Spoiler of one of them: if you’re a user of Android then the tips will help you increase time between charging your phone and improve your privacy.