BASF 3D Printing Solutions launches a new lineup of filaments under the Forward AM brand, which include three options characterized by different composition and hardness — Ultrafuse TPU 95A, Ultrafuse TPU 64D, and Ultrafuse TPS 90A.

BASF 3D Printing Solutions launches a new lineup of filaments under the Forward AM brand, which include three options characterized by different composition and hardness — Ultrafuse TPU 95A, Ultrafuse TPU 64D, and Ultrafuse TPS 90A.

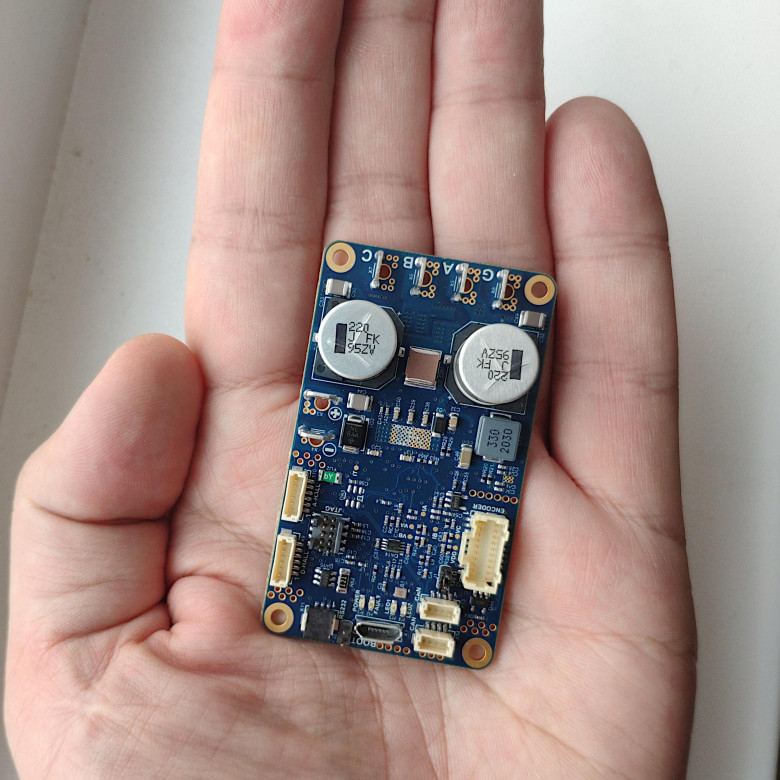

In this video, we are making a cable for connecting a quadrature encoder to a Servosila brushless motor controller, and and then running a servo motor in Direct Drive mode. To make the cable we are using a cable assembly kit that can be purchased from the internet store. Alternatively, the components for the cable can be bought in other places. The part numbers are given in the controller's datasheet.

The cable assembly kit consists of a connector and a set of wires with pre-crimped socket blades. If you have a crimper tool, you can also attach the socket blades to wires by yourself.

Lets open a datasheet document that comes with the brushless motor controller. Note that each connector has its first pin clearly marked with a "1" sign. Conventionally, the numbering of pins is done in such a way that there are rows of odd-numbered and even-numbered pins.

The quadrature encoder's electrical interface has 5 wires in total. Positions of the pins of each of the wires are given in the table. The socket blades need to be pushed into the connector until you feel a "click". The blades lock into the connector's sockets. Optionally, primarily for cosmetic reasons, you may want to add a heat-shrink tubing to your cable.

The brushless motor controllers come in two distinct forms, a circular and a rectangular one. Both models are identical in terms of capabilities, features, firmware, and external electrical connectors.

The connector has a locking mechanism that keeps it in place. I soldered a mating connector to the other side of the cable - a connector that my brushless motor needs. Note that your motor will likely require a different connector, or no connector at all. It is always a good idea to test an end-to-end integrity of the cable and its connectors. Lets buzz the wires using a multimeter. The cable is ready.

Nothing and nobody will escape oblivion. Whatever you may say, the history of mankind is a history of automation and the subsequent evolution of workers. This happened both during the first industrial revolution and during the second. The same thing happened with digital revolution. Now machine learning and artificial intelligence are being implemented everywhere. What is the future of software testing?

In this video, we will look at how to connect brushless motors to a Windows computer via USB. We are going to connect a network of Servosila brushless motor controllers to the computer. The other option is CANbus interface, but we will look at CANbus in a dedicated video. A regular USB cable is used. Note that the USB cable is not used to power the controller and its motor.

The first brushless motor controller in network appears to Windows as a Virtual COM port. Once connected via USB, it can be found in a general list of devices in the Window's "Settings" window. Up to 16 controllers can be connected this way via a single USB cable to the same control computer or a PLC. If one of the interconnected brushless motor controllers is connected to a computer via USB, then that particular controller becomes a USB-to-CANbus gateway for the rest of the network.

If your computer happens to have more that one serial port, you may wish to check a COM port's number assigned by Windows to the controller. Then, you pick this COM port in a drop down menu in the Servoscope software, and click Connect. If the COM port is not listed in the drop-down menu, click the Refresh button. If everything is good, the controller appears in a list of devices. Double-click to open up a control and configuration window.

In the comment sections of our articles about our server there are often users who say: "Why would you jump through so many hoops, when you can do the same with a single line of code in FFmpeg!?"

A few weeks ago we wrote an article about Docker and WebRTC servers and talked about the intricacies of launching containers. Our readers (rightly) questioned whether Docker was a suitable tool for production, for the following reasons:

In the previous article we refreshed our memory of WebRTC CDN and the ways this technology helps to minimize latency for WebRTC streams. We also discussed why load balancing and autoscaling wouldn't be amiss in CDNs. Here are the main points from the article:

The vast majority of IT specialists in various fields strive to perform manually as few actions as possible. I won't be afraid of the loud words: what can be automatized, must be automatized!

Let's imagine a situation: you need to deploy a lot of servers of the same type and do it quickly. Quickly deploy, quickly undeploy. For example, to deploy test rigs for developers. When development is carried out in parallel, you may need to separate the developers, so they don't impede each other and possible errors of one of them don't block the work of the others.

There may be several ways to solve this problem:

New issue of DataScienceDigest is here! OpenAI is launching a $100 million startup fund, Albumentations 1.0 has been released, lessons on ML platforms, image cropping on Twitter, and more.

Hi All,

I’m pleased to invite you all to enroll in the Lviv Data Science Summer School, to delve into advanced methods and tools of Data Science and Machine Learning, including such domains as CV, NLP, Healthcare, Social Network Analysis, and Urban Data Science. The courses are practice-oriented and are geared towards undergraduates, Ph.D. students, and young professionals (intermediate level). The studies begin July 19–30 and will be hosted online. Make sure to apply — Spots are running fast!

If you’re more used to getting updates every day, follow us on social media:

Telegram

Twitter

LinkedIn

Facebook

Regards,

Dmitry Spodarets.

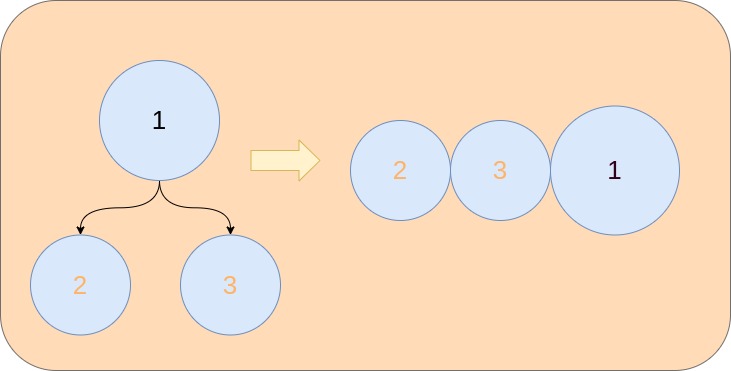

In this article, we discuss the postorder traversal of a binary tree. What does postorder traversal mean? It means that at first, we process the left subtree of the node, then the right subtree of the node, and only after that we process the node itself.

Why would we need to do it in this order? This approach solves an entire class of algorithmic problems related to the binary trees. For example, to find the longest path between two nodes we need to traverse the tree in a postorder manner. In general, postorder traversal is needed when we cannot process the node without processing its children first. In this manner, for example, we can calculate the height of the tree. To know the height of a node, we need to calculate the height of its children and increment it by one.

Let's start with a recursive approach. We need to process the left child, then the right child and finally we can process the node itself. For simplicity, let's just save the values into slice out.

One of our readers recommended paying heed to the Espressif IoT Development Framework. He found an error in the project code and asked if the PVS-Studio static analyzer could find it. The analyzer can't detect this specific error so far, but it managed to spot many others. Based on this story and the errors found, we decided to write a classic article about checking an open source project. Enjoy exploring what IoT devices can do to shoot you in the foot.

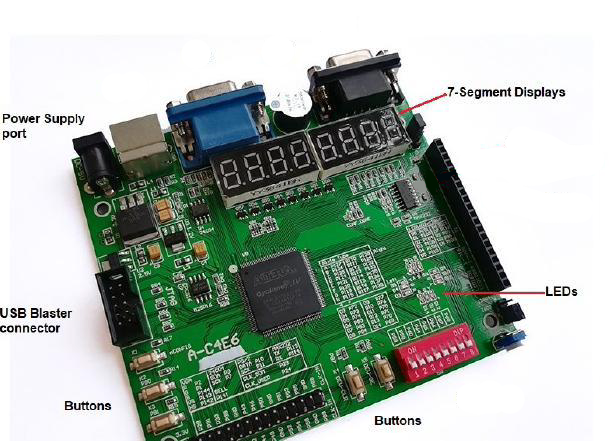

There are many situations when you need to protect your data, and different tools can be used to do that. For example, a safe. We develop a passcode data protection mechanism by using an FPGA board and Quartus Prime software. It allows demonstrating the basic concepts of a combination lock such as entering data, setting and checking a passcode, and displaying data.

The unique powers of quantum computation may give humanity an important weapon — or several weapons — against climate change, according to one quantum computer pioneer.One of the possible solutions for the excess carbon in the atmosphere and to reach global climate goals is to suck it out. It sounds pretty easy, but, in fact, the technology to do so cheaply and easily isn’t quite here yet, according to Jeremy O’Brien Chief Executive Officer, PsiQuantum, a quantum computing startup.