Participants of the 7th National Championship of End-to-End Working Professions of High-Precision Industries held in Yekaterinburg utilized Intamsys Funmat HT 3D printers allowing the use of refractory polymers.

Participants of the 7th National Championship of End-to-End Working Professions of High-Precision Industries held in Yekaterinburg utilized Intamsys Funmat HT 3D printers allowing the use of refractory polymers.

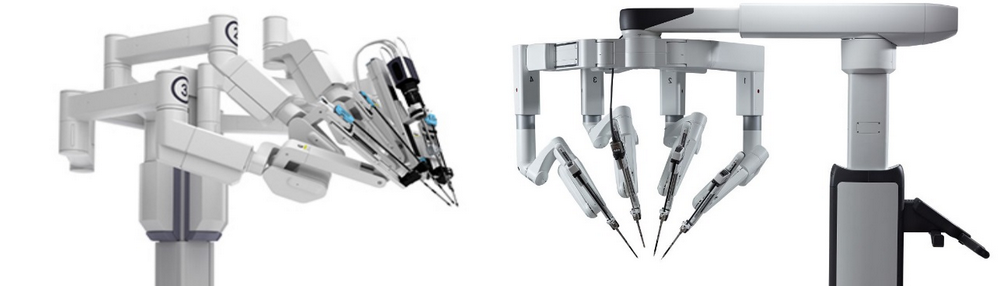

We continue to cover the world of robotics. In this article we will talk about how automated robotic systems that used to work only at the factories and plants, became utilized in medicine with further improvements. We will provide the real-world examples of such applications, as well as talk about equipment and the prospects of doctors and robots working together.

A turboprop Catalyst is a powertrain of the new single-engine business jet Beechcraft Denali. The Catalyst was developed by General Electric with the extensive usage of 3D printing. Additive technologies helped to unite 855 parts into 12 components.

Russian 3D scanner manufacturer Thor3D launches its new device: the Calibry Mini.

Made for scanning smalled objects, this affordable and lightweight solution, designed to be easy to use, can be a good choice for education and medical fields, as well as arts and museums.

Anna Zevelyov, CEO of Thor3D, mentions that the device will grant the doctors the ability to scan any part of the body and even perform full-body scans. Museums will now be able to capture various collections with art objects of different sizes. She adds that their engineers conducted multiple tests before release that showed impressive results.

According to her, the device will be a great addition to the company’s portfolio, making their Calibry product line even more versatile and compelling.

The jewelry restoration was done with the help of both computer technologies and traditional methods. Wax, clay and bronze were used.

The archeologists restored a jewelry object made in the Iron Age. It was done with the help of digital technologies.

Restoration included scanning of the clay molds that were used for casting bronze in the 1st and 2nd centuries B.C. Original molds found in Cairns, at South Ronaldsay island of Orkney islands, Scotland, were too fragile to use for jewelry.

Ben Price, a PhD student at the University of the Highlands and Islands, department of Archeology. Around 80 fragments of clay molds were found during the recent excavations of a broch dating back to the Iron Age in Cairns.

Hello everyone! This article is focused on the Scan Tech iReal 2E device. This full-color 3D scanner is designed to digitize art objects and humans. The machine isn’t pretending to be the most accurate solution out there but it excels at capturing color and complex geometries, including hair. It’s also very fast.

The Italian national cycling team is preparing for the Tokyo Olympics. They use a handheld Calibry 3D scanner by a Russian manufacturer Thor3D to improve the aerodynamics of their bicycles.

The brands Pinarello and Hardskin asked 3DiTALY (Thor’s 3D official partner in Italy) to digitize the bicycles using the Calibry 3D devices. The results were used to adjust the aerodynamics of the bikes..

This is a moment when Joseph Prusa, a godfather of 3D printers with the kinematics named after him, released a 3D printer with a CoreXY kinematics. But his team isn’t planning to move away from an older solution. In this article we will talk about what the Original Prusa XL will look like, as can be seen in the pictures from the Formnext 2021 exhibition.

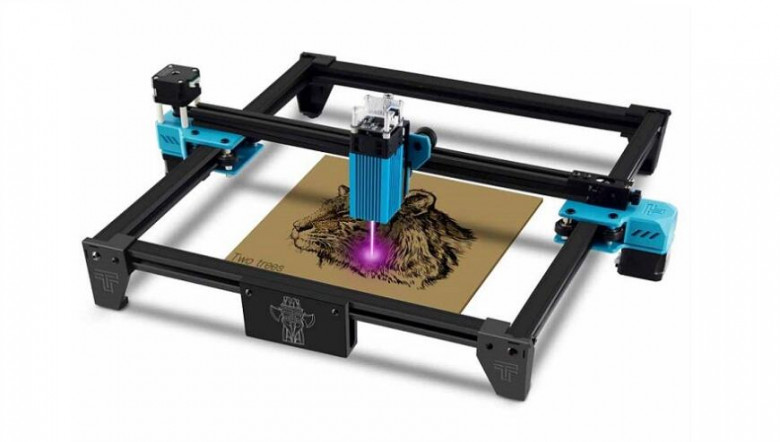

Today, we will talk about a useful tool in the workshop of any maker, a good addition to carpentry and additive equipment, which makes it possible to process the surfaces of various materials — the engraving and cutting machine TwoTrees TT-5.5S with a powerful diode laser.

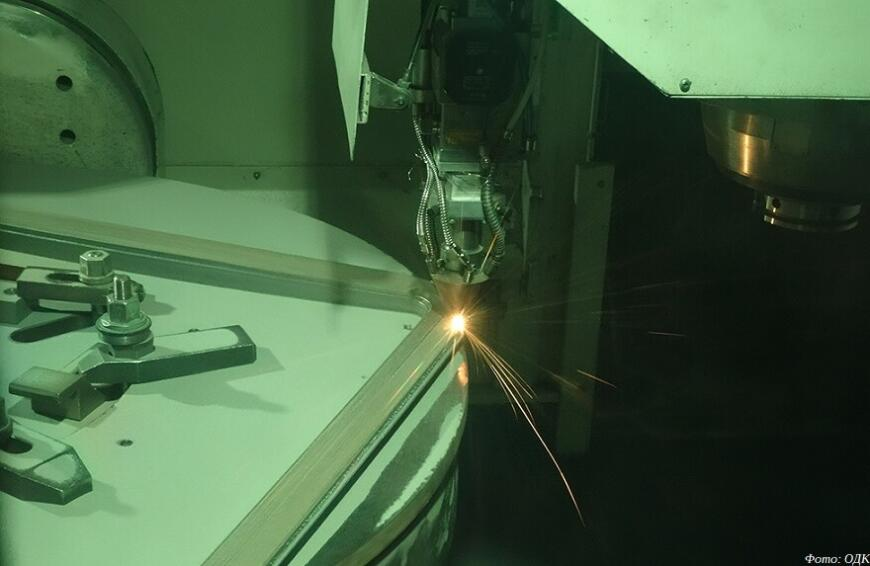

Research Institute of Technology and Organization of Engine Production (NIID, a part of United Engine Corporation, UEC, of Rostec) is continuing the research focused on using additive manufacturing technologies for aircraft engine production with the help of metal 3D printing. The hybrid manufacturing system was launched in 2020 and so far it produced 11 full-size billet engine parts.

We have previously written about how the Raise3D Pro2 is used for printing surgical guides. In this article, we will talk about intervertebral cages developed and patented by the Pozvonoq startup of the North-West Technology Transfer Center and the Russian manufacturing company Ortoinvest, which specializes in the development and production of power equipment and implants for traumatology and orthopedics.

The Bengbu Hospital in the Anhui Province makes use of additive technologies to create medical visuals and guides for vertebrae surgery. Back in 2013, director of orthopedics Niu Guoqi launched the research of 3D printing application for vertebrae, aiming to establish it in-house.

Director Niu’s team and the whole project were the first to apply 3D printing technology for healthcare applications in the Anhui Province. The device they employed was the Raise3D N2 Plus 3D printer from the manufacturer’s very first lineup. The team appears to find it extremely efficient.

“[The Raise3D N2 Plus] printer is the most stable one among all I have tried. The print quality is really good. The surface features of the bone are all recovered in the printed model,” comments Niu Guoqi on the use of the machine in vertebrae surgery, which is one of the most complex and riskiest for doctors.

I reinstalled both Windows and Linux (Fedora) recently on a notebook PC, and I decided to write the summary article about my experience with both OS. I'm also going to describe how to configure each OS via command-line and set up a dual-boot system.

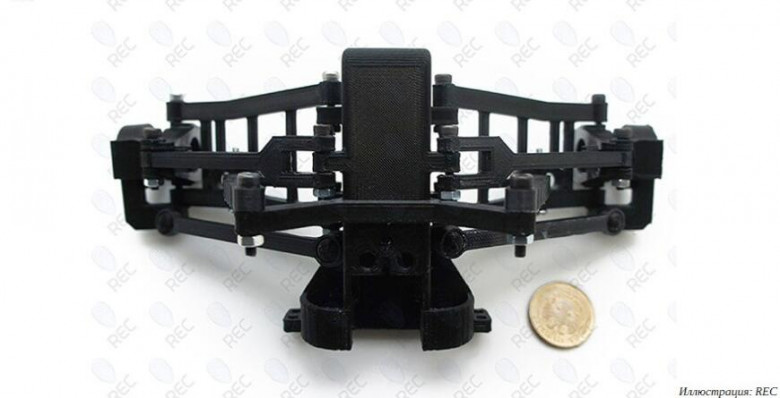

The management of a Russian company REC (that’s been developing and manufacturing 3D printing materials for nine years) thinks that the relevance of the additive manufacturing industry will only continue to grow as long as the market will become even more aware of the abilities of the tech.

Hi! I am Aleksey Rybakov, Product Owner at Sber ARVR Lab.

And before telling you what we have achieved, let me explain the meaning of this article’s heading. Or more so, explain the word “metauniverse”. This term was well-described by Mark Zuckerburg: “Metauniverse is internet implemented, where instead of looking at internet, you are inside of it.” Like a parallel universe, which you can enter yourself with AR/VR gadgets or through a 3D-avatar.

In other words, a metauniverse is simultaneously a virtual space and a way of engaging with its objects without the common “screen + keybord/mouse/sensor” medium.

And yes, metauniverses are here. But to get into one, you’ll need a few things. First, you need to know where to look. We will talk about that later when depicting a curious case in Moscow. Second, you need a technology that will help connect the virtual world with the real one. We will talk about that as well.

Now, let me introduce: VPS.

“This is not even a hypercar — it’s an ultracar,” — this is how race car driver Spyros Panopoulos prefers to call his brainchild, whose company is going to present the most powerful production car in the world, stuffed with 3D printed parts and ready to put to shame Formula 1’s SSC Tuatara and Bugatti Chiron.

The Swiss manufacturer of professional 3D printers Sintratec has released a software solution called Nesting, which allows for automatic placement of models in additive systems based on selective laser sintering (SLS) technology with optimal use of the build volume.

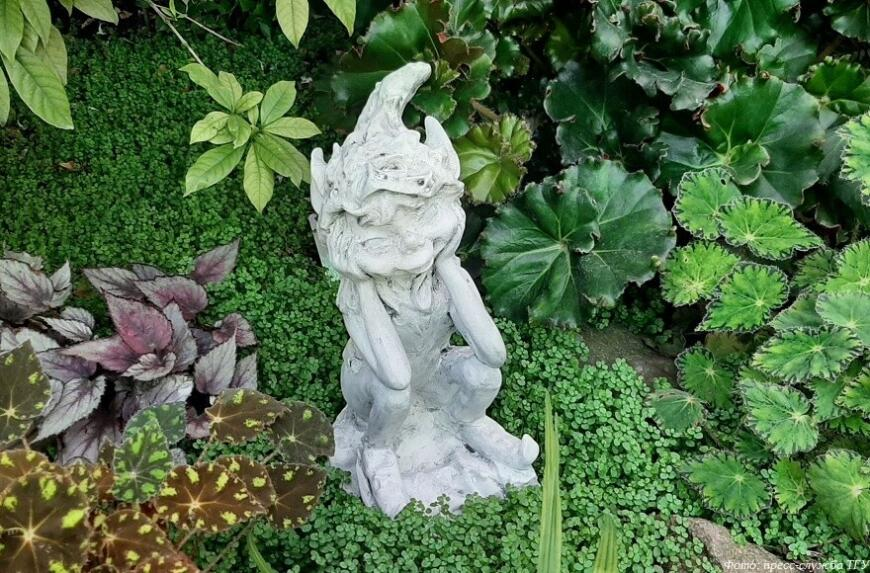

In the subtropical greenhouse of the Siberian Botanical Garden of Tomsk State University, there appeared 3D printed sculptures of mythological characters — elves, a winged cat, and a baby dragon.

The idea was to create moisture-resistant photogenic sculptures that would complement the exposition of greenhouse plants and draw the attention of visitors to the mythical creatures of the world cultural heritage. 3D models of the sculptures were designed and printed on a 3D printer, being then polished and painted to look like stone.

The research-and-development center of JSC KAMAZ (‘Kama Automobile Plant’) engaged in the creation of advanced vehicle models and improvement of the operational properties of manufactured equipment has recently acquired a CT Mini M vacuum forming machine for their pilot production.

Engineers at the Institute of Mechanics of Moscow State University have designed and manufactured a walking robot using 3D printing technologies with composite materials and aluminum alloys.